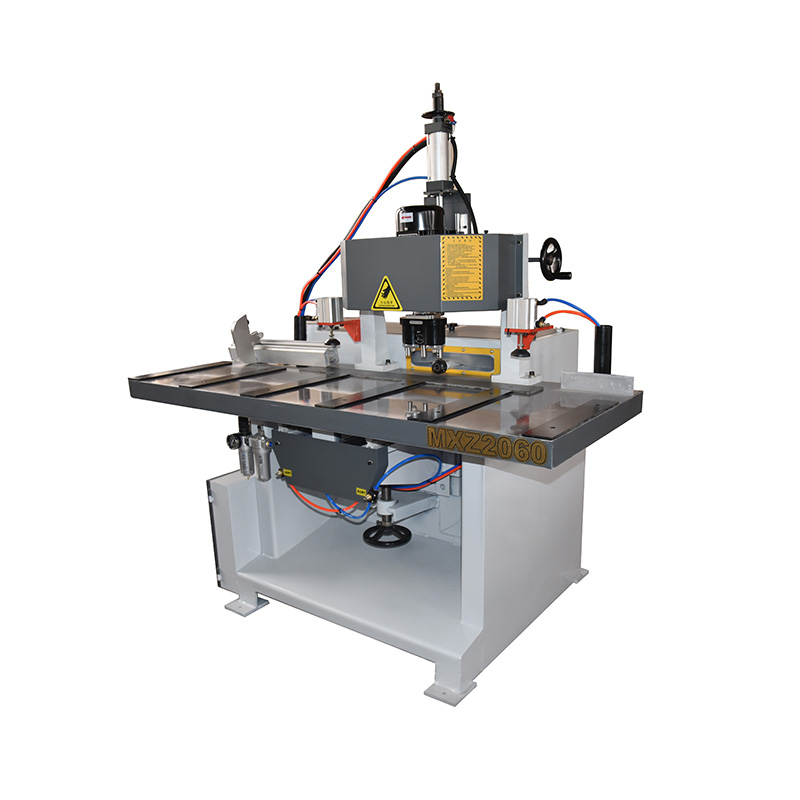

Door Lock Slot Milling Machine

Door Lock Slot Milling Machine is a very important equipment in woodworking machinery. It is used for milling and drilling slots in the plane and side keyhole shapes of wooden doors.

Machine Detail:

Specification:

| Max milling length | 220 mm |

| Max milling depth | 120 mm |

| Max milling width | 30 mm |

| Working lift height | 100 mm |

| Main spindle speed | 1000 r/m |

| Power | 0.75/1.1 kw |

The Door Lock Slot Milling Machine is a very important equipment in woodworking machinery. It is mainly used for processing wooden doors, door frames, window frames, sash slots, door locks, door lock steps, door lock hinges, and one-time completion; used for wooden door planes and sides The keyhole-shaped milling and drilling slot forming can also be used for slotting and drilling of wooden furniture; conveniently and accurately control the processing and production requirements of door lock slots and hinges.

The Door Lock Slot Milling Machine is generally composed of mechanical components such as milling cutters, milling slots, worktables, motors, and variable-speed drill sets. These mechanical components have their own functions and characteristics. These components work closely together, coordinate with each other, and have relative Independence; the operator is generally able to perform simple operations with high work efficiency.

Machine Introduction:

1. The Door Lock Slot Milling Machine is made of high-quality steel plate by bending and forming, which is processed by high temperature treatment.

2. The plane position and shape of the keyhole are formed by imitating milling, and the mold can be made by MDF, which is convenient and efficient.

3. The long and short grooves of the lock hole of the wooden door are controlled by frequency conversion, the eccentric wheel swings back and forth milling, and the special positioning device can realize automatic milling and shaping.

4. Horizontal and vertical feed sliding, adopting square linear guide bearing, high precision, low noise, sensitive and reliable, stable and long service life.

5. The cutting tool adopts new type cutting tool, which is sharp. The motor variable speed drill set is configured and used, and the effect is excellent.

6. The pressing device adopts air cylinder for pressing, which is sensitive and reliable.

7. Simple adjustment and operation, saving time and effort.

8. Safe and reliable, as long as the switch is not pressed tightly during operation, all power cannot be started. When abnormality occurs during work, it will stop automatically.

Daily maintenance:

(1) Check the fastening bolts and nuts everywhere, and tighten them.

(2) Check the connection of each organization, and remove any abnormalities. Lubricate the drilled connection parts.

(3) Check the pneumatic system.

(4) Check the electrical system: After turning on the power, check the direction of rotation of the motor.

(5) Keep the equipment tidy and clean the dirt on the workbench.