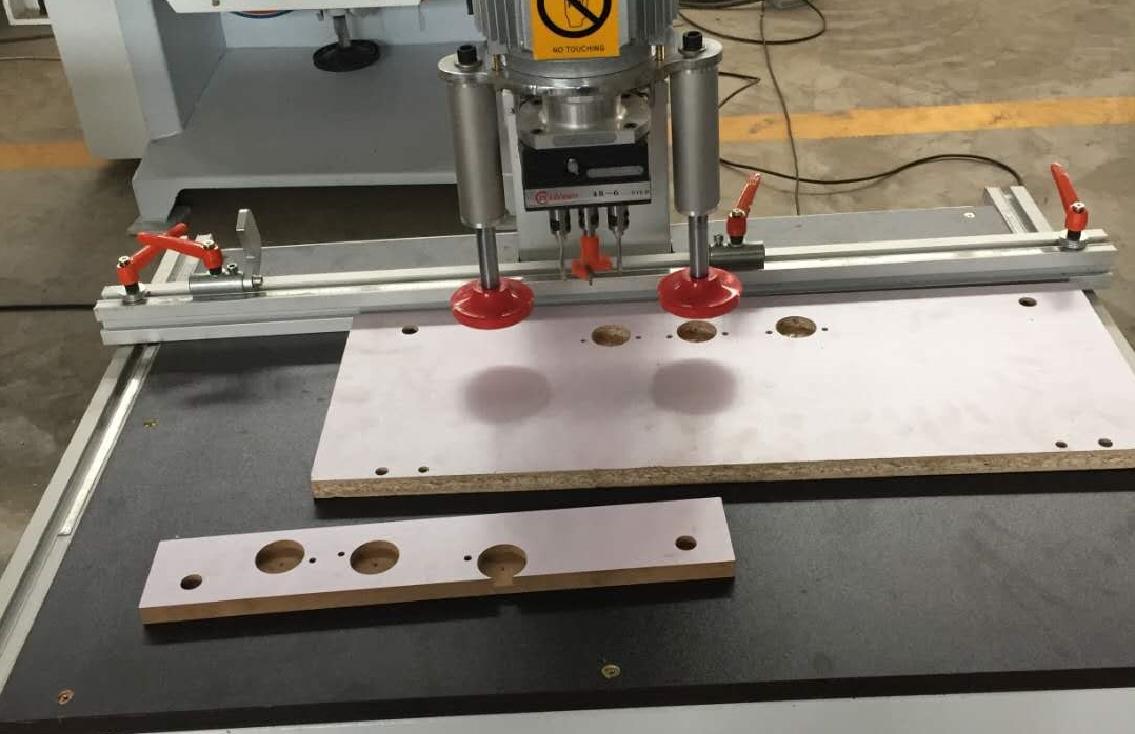

Hinge Boring machine

Hinge Boring machine is a widely used woodworking machinery.

Machine Detail:

Specification:

| Type | MZB73031 | MZB73032 | MZB73033 |

| Max drilling diameter | 50mm | 35 mm | 35 mm |

| Max drilling depth | 60mm | 60 mm | 60 mm |

| Distance between 2 heads | / | 185-870 mm | 185-1400 mm |

| Number of spindles | 3 | 3spindle*2heads | 3spindle*3heads |

| Rotating speed | 2840r/min | 2840 r/min | 2800 r/m |

| Motor power | 1.5kw | 1.5kw * 2 | 1.5kw * 3 |

| Pneumatic pressure | 0.6-0.8MPa | 0.6-0.8 Mpa | 0.6-0.8 Mpa |

| Overall dimension | 800*570*1700mm | 1300*1100*1700mm | 1600*900*1700mm |

| Weight | 200kg | 400 kg | 450 kg |

Machine Introduction:

Hinge, also known as hinge, is a mechanical device used to connect two solid bodies and allow relative rotation between them. The hinge may be composed of a movable component, or may be composed of a foldable material. The hinges are mainly installed on doors and windows, and the hinges are more installed on the cabinets. According to the material classification, they are mainly divided into stainless steel hinges and iron hinges; in order to let people get better enjoyment, hydraulic hinges (also called damping hinges) have appeared. Its characteristic is to bring a buffer function when the cabinet door is closed, which minimizes the noise caused by collision with the cabinet body when the cabinet door is closed.

Hinge drilling machine is mainly used to drill the door hole of panel furniture. It has a simple design, novel and generous, stable operation, simple operation, precise drilling position, flexibility, and high efficiency. It is an ideal equipment for cabinets, wardrobes and door manufacturers. The Hinge drilling machine can complete 3 holes in the vertical direction at one time or separately. One of the large holes is the hinge head hole, and the other is the assembly screw hole.

Daily maintenance:

(1) Check the fastening bolts and nuts everywhere, and tighten them.

(2) Check the connection of each organization, and remove any abnormalities. Lubricate the drilled connection parts.

(3) Check the pneumatic system.

(4) Check the electrical system: After turning on the power, check the direction of rotation of the motor.

(5) Keep the equipment tidy and clean the dirt on the workbench.