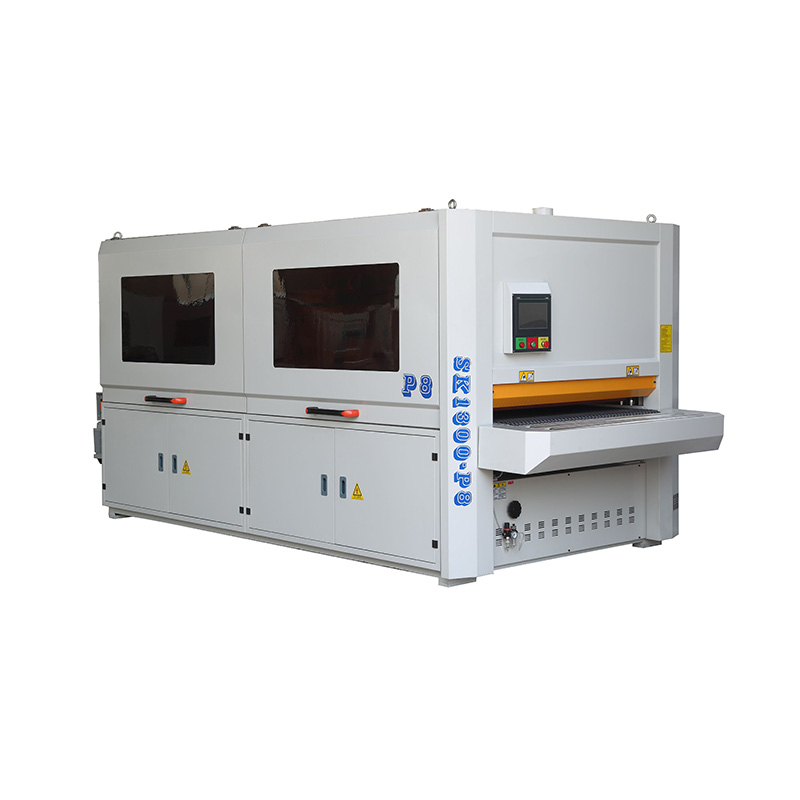

Best Sanding Machine Woodworking - Wide Belt Sanding Machine – Gladline

Best Sanding Machine Woodworking - Wide Belt Sanding Machine – Gladline Detail:

Wide Belt Sander is an equipment that uses abrasive tools to perform sanding or grinding of various board and wood products.

Machine Detail:

Specification:

| Model | R-RP630 | R-RP1000 | R-RP1300 |

| Working width | 630mm | 1000mm | 1300mm |

| Min. working length | 500mm | 500mm | 500mm |

| Working thickness | 10-100mm | 10-100mm | 10-100mm |

| Feeding speed | 5-25m/min | 5-25m/min | 5-25m/min |

| Power | 20.37kw | 27.87kw | 63.55kw |

| Abrasive belt size | 650*1920mm | 1020*2020mm | 1320*2200mm |

| Working air pressure | 0.6Mpa | 0.6Mpa | 0.6Mpa |

| Volume of dust collection device | 6500m³/h | 15000m³/h | 15000m³/h |

| Air Consumption | 12 m³/h | 17 m³/h | 17 m³/h |

| Overall dimensions | 1500*1250*2050mm | 1500*1550*2050mm | 2150*2900*2150mm |

| Net weight | 1800kg | 2200kg | 3200kg |

Precautions for use of Wide Belt Sander:

⒈When the Sanding Machine is in operation, the sanding disc, grinding wheel, belt, and polishing wheel may be broken and exploded at any time. When operating, you must wear glasses, helmets and other corresponding protective equipment.

⒉When the machine is running, it is strictly forbidden to touch the abrasive belt, grinding wheel, grinding head, polishing wheel, etc.

⒊The machine without effective protection measures cannot be used

⒋A lot of dust will be generated during sanding, so wear a mask to use

⒌The sanding equipment should be installed in a dry, ventilated place without direct sunlight

⒍When the automatic sanding machine is used, there must be matching dust removal equipment, otherwise it is very easy to malfunction, damage the equipment, and affect production.

⒎When belt sanding is found to be off-track, it should be adjusted in time.

⒏Wheel type sanding must confirm the accurate running direction of the grinding wheel, and lock the grinding wheel to prevent the grinding wheel from flying out.

Wide Belt Sanding Machine is a woodworking machinery manufacturer, mainly for woodworking board processing industry, floor wall board processing industry, bamboo and wood crafts processing industry, bamboo and wood toy processing enterprises, specially developed sanding equipment, with simple operation and high degree of automation , The characteristics of high production efficiency, mature and stable technology, complete supporting facilities, etc., can be perfectly connected with automatic production lines to form various automatic production lines.

Product detail pictures:

Related Product Guide:

We usually keep on with the principle "Quality To start with, Prestige Supreme". We've been fully committed to offering our purchasers with competitively priced excellent solutions, prompt delivery and skilled support for Best Sanding Machine Woodworking - Wide Belt Sanding Machine – Gladline, The product will supply to all over the world, such as: Danish, Leicester, New Zealand, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we give our clients with high quality products and solutions and excellent service. Be sure to feel free to contact us for further information.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!