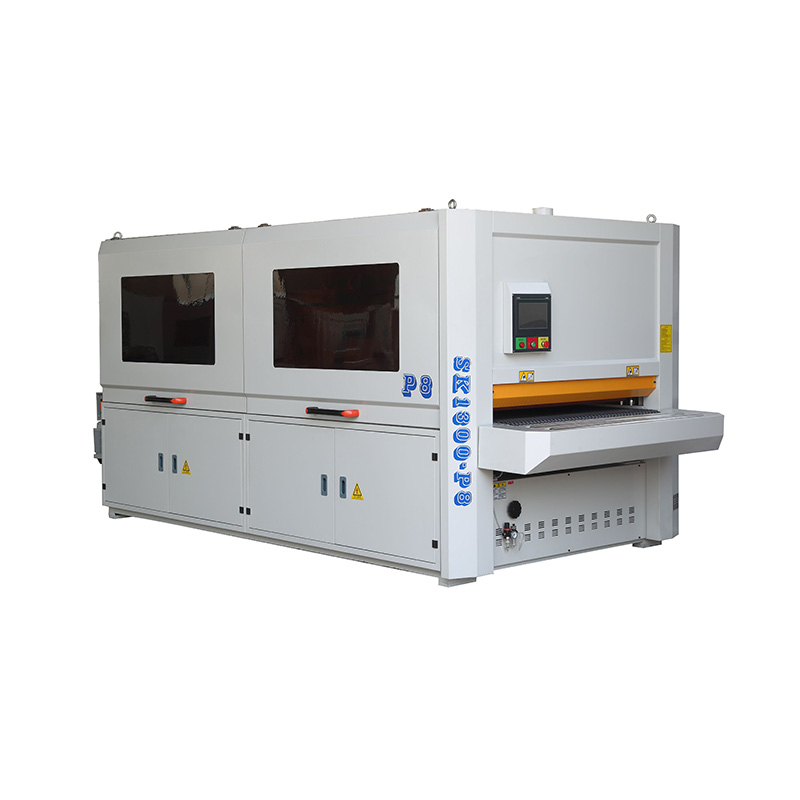

Low price for Manual Control Wood Edge Banding - Automatic Edge Banding Machine GE360K – Gladline

Low price for Manual Control Wood Edge Banding - Automatic Edge Banding Machine GE360K – Gladline Detail:

Automatic Edge Banding Machine GE360D can perform straight edge banding.

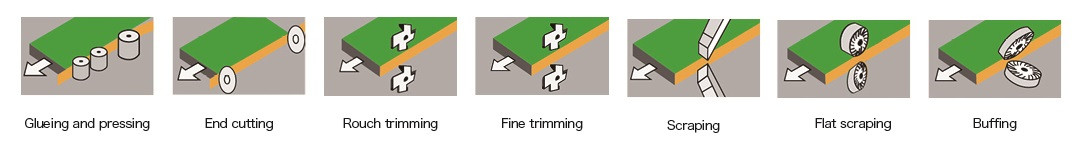

Function is as below:

Machine Detail:

Edge bander is a necessary machine for plate-type furniture production.

It is suitable for straight edge banding and trimming of medium density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc.

Specification:

| Machine Group | Automatic Edge Banding Machine |

| Function | Gluing and Press->End Cutting->Rough Trimming->Fine Trimming->Scraping->Flat Scraping->Buffing |

| Total Power | 10.3KW |

| Feeding Speed | 15-23m/min |

| Edge Band Thickness | 0.4-3mm |

| Panel Thickness | 10-60mm |

| Panel Length | ≥150mm |

| Panel Width | ≥40mm |

| Work air pressure | 0.6Mpa |

| Min panel size (L*W) | 350*40mm, 150*150mm |

| Weight | 1000kg |

| Machine Size | 4500*830*1610mm |

Automatic Edge Banding Machine Features:

1. Gluing: According to the unique structure, the glue on both sides of the edging board and the edging raw materials is evenly distributed to ensure a stronger bonding force.

2. All heads: According to the high-precision linear slide track fitness exercise, the automatic tracking and high-frequency motor motor are selected for rapid drilling structure to ensure that the disconnected surface is flat and clean.

3. Rough trimming and fine trimming: Both use the imitation full-automatic tracking and high-frequency motor structure to ensure that the left and right parts of the blank holder are leveled and clean. It is used to repair unnecessary edging raw materials around the edge band of the production and processing board.

1) Rough trimming function: The rough repair knife is a round knife. In order to solve the unnecessary part of the refurbishment of the wood board. Since the product finishing knife R-shaped knife cannot be used immediately when sealing the wood board, the wood board is generally 0.4mm thick. If the product finishing knife is used immediately, it is very easy to cause cracks. In addition, rough repair can also be used as the first level repair process when sealing PVC and acrylic sheets.

2) Fine trimming: The product finishing knife is an R-shaped knife. The key is to customize the edge bands of PVC and acrylic panels for custom furniture, and the edge bands above 0.8 mm thick are appropriate.

4. Scratching: Used to remove the wave pattern marks caused by the non-uniform linear movement of the trimming, so that the left and right parts of the board are more smooth and clean.

5. Polishing: Use a pure cotton polishing cloth wheel to remove the processed board, and according to the polishing to make the inner hole of the hemming smoother.

Product detail pictures:

Related Product Guide:

Our commission would be to serve our customers and clientele with very best excellent and aggressive portable digital products for Low price for Manual Control Wood Edge Banding - Automatic Edge Banding Machine GE360K – Gladline, The product will supply to all over the world, such as: UK, Spain, Lesotho, We are proud to supply our products to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!