Automatic Edge Banding Machine GE365

Automatic Edge Banding Machine is one of the equipment that the panel furniture manufacturers will purchase, and it is an indispensable equipment in the panel furniture production line.

Machine Detail:

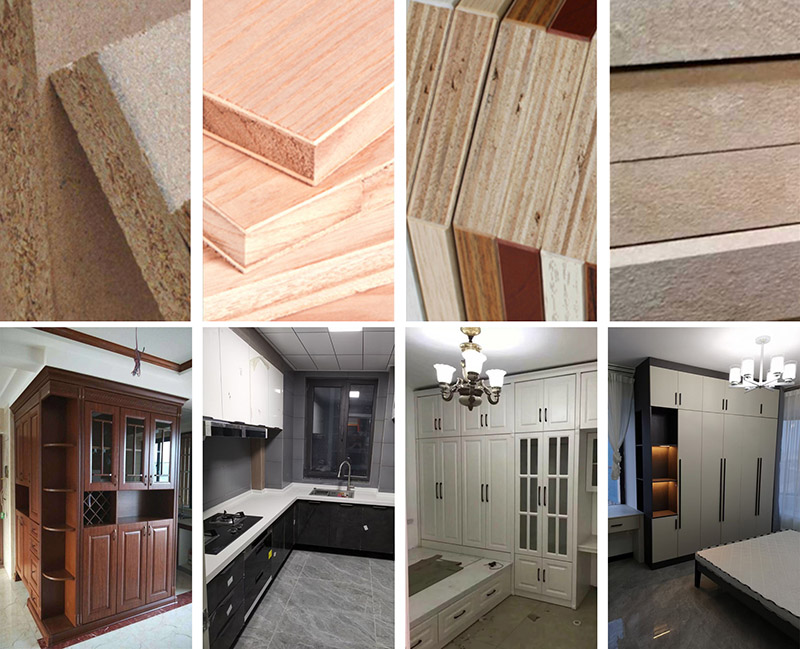

Edge bander is a necessary machine for plate-type furniture production. It is suitable for straight edge banding and trimming of medium density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc.

Specification:

| Machine Group | Automatic Edge Banding Machine |

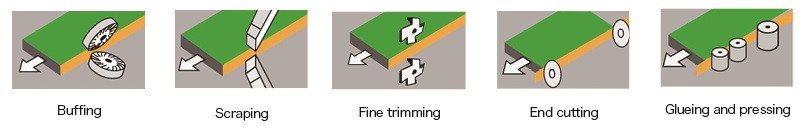

| Function | Gluing and Press->End Cutting->Fine Trimming->Scraping->Buffing |

| Total Power | 8.3KW |

| Feeding Speed | 15-23m/min |

| Edge Band Thickness | 0.4-3mm |

| Panel Thickness | 10-60mm |

| Panel Length | ≥150mm |

| Panel Width | ≥40mm |

| Work air pressure | 0.6Mpa |

| Min panel size (L*W) | 350*40mm, 150*150mm |

| Weight | 1300kg |

| Machine Size | 3938*830*1610mm |

Edge banding is an important process in the manufacturing process of panel furniture. The quality of edge banding directly affects the quality, price and grade of the product. By sealing the edges, the appearance quality of the furniture can be well improved, and the corners of the furniture can be prevented from being damaged during transportation and use, and the veneer layer is lifted or peeled off. At the same time, it can waterproof, seal the release of harmful gases and reduce deformation, etc. It can beautify the furniture and make the mood happy. The raw materials used by panel furniture manufacturers are mainly particleboard, medium-density board and other man-made boards. The main edge bands selected are PVC, polyester, melamine and wood strips.

Different materials and specifications of edge banding use different Edge Banding Machine. Nowadays, the Edge Banding Machine used by furniture manufacturers mainly include manual straight-curve Edge Banding Machine and automatic straight-line Edge Banding Machine. The manual Edge Banding Machine has a relatively simple structure, and its installation, use and maintenance are relatively easy; the fully automatic linear Edge Banding Machine has a complex structure, high manufacturing precision and high production efficiency. Customers can make a reasonable choice according to their actual needs.

Application:

Advantage:

●The edge banding machine body is made of 18mm national standard high-strength steel plate, exclusive welding technology, box-type body structure, after high temperature quenching treatment, it is not easy to be deformed for a long time, and the heavy-duty gantry machining center is processed in one time. The flatness is extremely high!

●Conveyor belt guide rails are made of bearing steel, chrome-plated, wear-resistant and not easy to rust, high straightness, low friction coefficient, and stable conveying at a uniform speed!

●The conveying motor adopts customized models, high power, stable power output, and has a thermal protection system to increase the safety factor!

●The high-speed motor, full-head guide rail, pneumatic system, air cylinder, safety valve and frequency converter all adopt well-known brands. Highly sensitive Airtac magnetic switch and high flexible shielded cable.

●Automatic air return solenoid valve to ensure the stability of 5 million operations. Equipped with air pressure stabilization control to ensure continuous and stable machine action in all aspects!

●The edge banding machine body is processed and formed by CNC machining center at one time and is assembled with imported bearings with an error of 0.05mm to ensure smooth and smooth overall trimming effect.

●The edge banding machine body is laser cut, the surface is flat, no indentation, no burrs, and high dimensional accuracy. All machine parts are processed by imported CNC, with high precision, ensuring long service life and precise operation of the parts!

●The conveyor chain block is made of high-quality silica gel by one-time die-casting, and its wear resistance meets international standards, and it is smooth and non-jumping. Ensure that the edge banding machine achieves good stability.

FAQ:

Q1: Are you a factory?

A: We are a specialized woodworking machinery manufacturer

Q2: Can I make an OEM order?

A: Yes, we accept OEM and customized

Q3: How do I do the installation of the edge banding machine?

A: We provide installation guide for you and if it is necessary, we will send our installation team to job site.

Q4: Do you have a MOQ?

A: 1 set

Q5: How long is the warranty?

A: 1 year

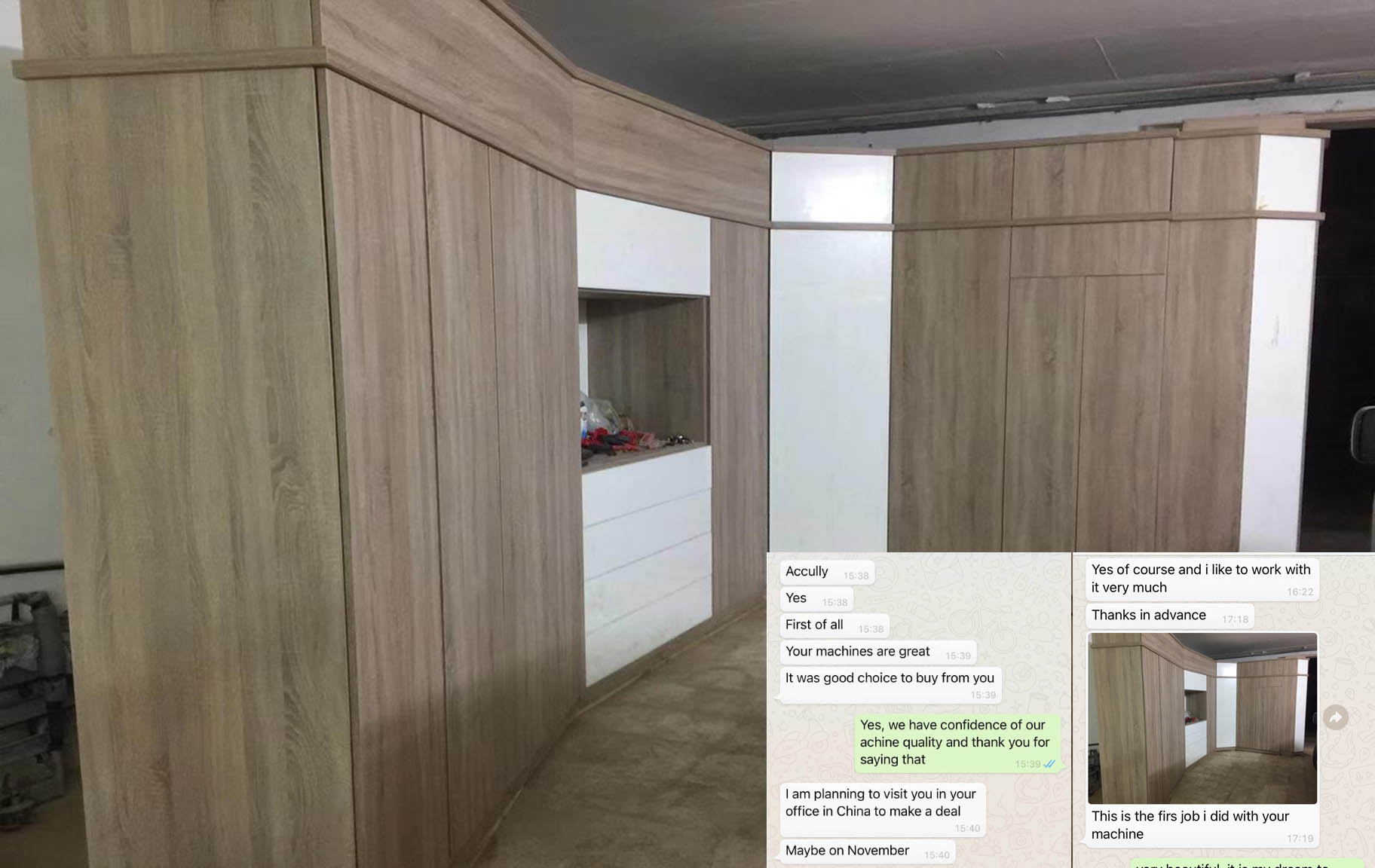

Customer Feedback:

Package: