Wood Gluing Spreader Machine Manufacturers - Gluing Spreader – Gladline

Wood Gluing Spreader Machine Manufacturers - Gluing Spreader – Gladline Detail:

Specification:

|

Technical Data |

MT6106 |

MT6206 |

MT6113 |

MT6213 |

| Surface | Single | Double | Single | Double |

| Max glue spreading width /mm | 600 | 600 | 1300 | 1300 |

| Max working thickness /mm | 60 | 60 | 60 | 60 |

| Rubber roller diameter /mm | 200 | 200 | 200 | 200 |

| Glue spreading speed /m/min | 24 | 24 | 23 | 23 |

| Motor power /kw | 1.5 | 1.5 | 2.2 | 2.2 |

| Overall dimension /mm | 1150*800*1300 | 1150*970*1300 | 2100*900*1300 | 2100*1000*1300 |

| Net weight /kg | 400 | 400 | 600 | 600 |

Gluing Spreader Instruction:

1. The gluing spreader should be inspected every day before use. If foreign matter is found, it should be cleaned up in time to check whether the equipment is lubricated normally and whether the moving parts are running flexibly.

2. After the test run is normal, inject the glue into the glue tank, and then adjust the gap between the glue rollers according to the thickness of the veneer and the viscosity of the glue, and

The gap between the glue roller and the glue roller.

3. Care should be taken to clean the surface of the veneer during the gluing process to prevent sharp debris from scratching the rubber layer on the surface of the gluing roller; the surface grooves of the rubber layer caused by long-term use should be repaired in time.

4. After a long period of shutdown and the end of daily work, in order to prevent the glue from solidifying, the gluing spreader should be thoroughly cleaned, and the glue roller, squeeze roller and glue tank should be cleaned, and the glue sprayed all over the fuselage should be cleaned. It also needs to be completely removed. After cleaning, pay attention to wipe dry water stains to prevent rust.

5. When the gluing spreader is out of service, it should be restored to the factory state; adjust the upper glue roller and squeeze roller back to the initial position, rotate the adjustment nut of the glue roller and the adjustment sleeve of the squeeze roller to adjust the glue roller The compression spring and the squeezing roller top spring are completely relaxed, and all parts are fully lubricated and equipment maintenance is carried out.

Veneer gluing is an important process in the production of plywood. The quality of gluing not only affects the veneer’s bonding strength and the physical and mechanical properties of the plywood, but also affects the production cost of the plywood. Therefore, mastering the structure and working principle of the veneer gluing machine and the adjustments related to the glue quality will help to use the veneer gluing machine correctly and rationally.

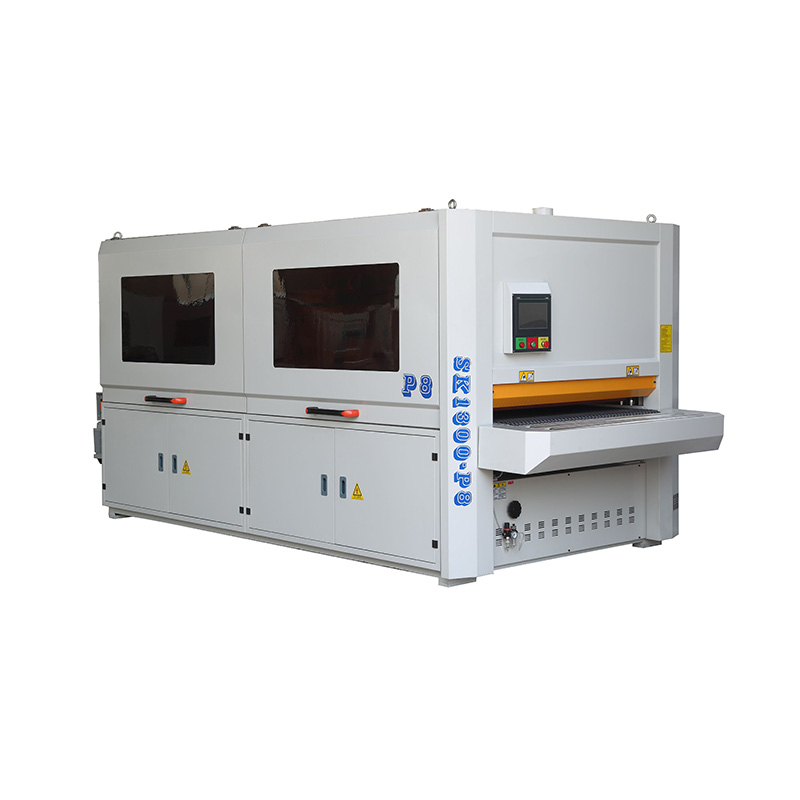

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and superb good quality control throughout all stages of manufacturing enables us to guarantee total buyer gratification for Wood Gluing Spreader Machine Manufacturers - Gluing Spreader – Gladline, The product will supply to all over the world, such as: Naples, Chile, South Africa, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to provide professional, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We will serve you with all sincerity!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!