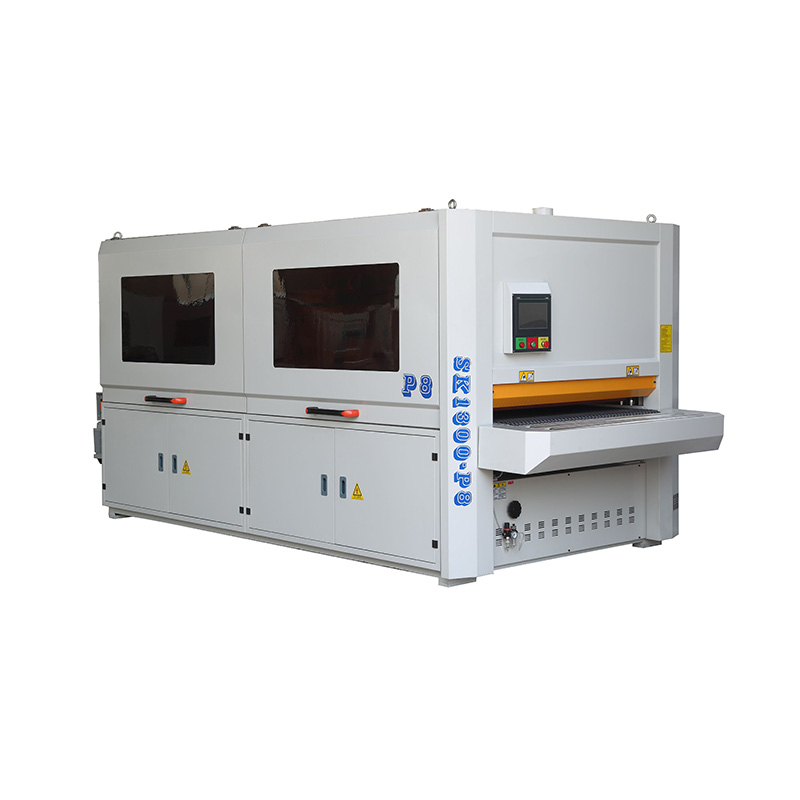

Wholesale Plywood Sanding Machine - Brush Sanding Machine – Gladline

Wholesale Plywood Sanding Machine - Brush Sanding Machine – Gladline Detail:

Brush Sanding Machine sands and polishes wooden doors, cabinet doors, shutters, furniture, picture frames, carved furniture and other parts before and after painting

Machine Detail:

Specification:

| Model | SK1000P8 |

| Working width | 1000mm |

| Min. Working length | 500mm |

| Working thickness | 2-150mm |

| Polishing roller speed | frequency control |

| Feeding speed | 3-12.5m/min |

| Total motor power | 19.81kw |

| Overall dimensions | 4470*1850*2100mm |

| Net weight | 4500KG |

Irregular shape is the production of irregular products, which refers to solid wood carving products. In many practical applications, the products carved by the engraving machine will have wood chips and rough edges, which need to be polished and repaired by a special-shaped sanding machine. The Brush Sanding Machine can repair deep grooves and uneven parts of the product

Brush Sanding Machine introduction:

1. The maximum feeding speed is 42m/min, and the production efficiency is high and suitable for mass production.

2. The speed of the abrasive belt and the grinding wheel is adjusted by frequency conversion, which is stable and accurate for different materials of workpieces, different painted surfaces and different types of sanding materials.

3. The sand rack is equipped with an oscillating device and a dust blowing function to ensure a smooth and uniform processing surface, which can effectively prevent the sanding belt from running and increase the service life of the sanding belt.

4. The sand head can automatically compensate the consumption of the grinding wheel according to the length of the sanding workpiece to reduce the cumbersome manual compensation.

5. The multi-point, segmented, multi-angle material pressing method can smoothly convey various workpieces with irregular surfaces.

6. The left and right side of the workpiece are conveyed by wheeled side pressure to prevent the left and right swing of the workpiece and correct the left and right bending of the workpiece during the grinding process, which can effectively avoid the friction damage to the workpiece surface.

7. The adjustment of the equipment is convenient and fast. The adjustment time of each line is about: 30min.

8. The effective sanding is more than 95%, which can completely replace the tedious manual sanding.

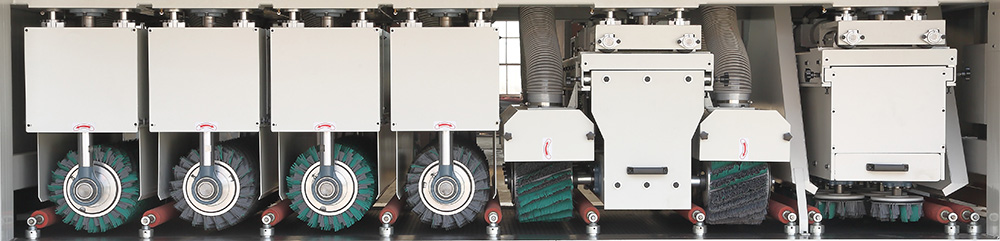

Product detail pictures:

Related Product Guide:

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of Wholesale Plywood Sanding Machine - Brush Sanding Machine – Gladline, The product will supply to all over the world, such as: Paraguay, Russia, Sudan, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!