Original Factory China High Quality Automatic Wood Turning Lathe Machine with Sanding

We’ll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for Original Factory China High Quality Automatic Wood Turning Lathe Machine with Sanding, We’ve been sincerely searching forward to cooperate with prospects all over the environment. We imagine we are able to satisfy with you. We also warmly welcome consumers to go to our manufacturing unit and purchase our solutions.

We’ll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for Brush Sanding Machine, China Wood Lathe, Sanding Machine, With nearly 30 years’ experience in business, we have been confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

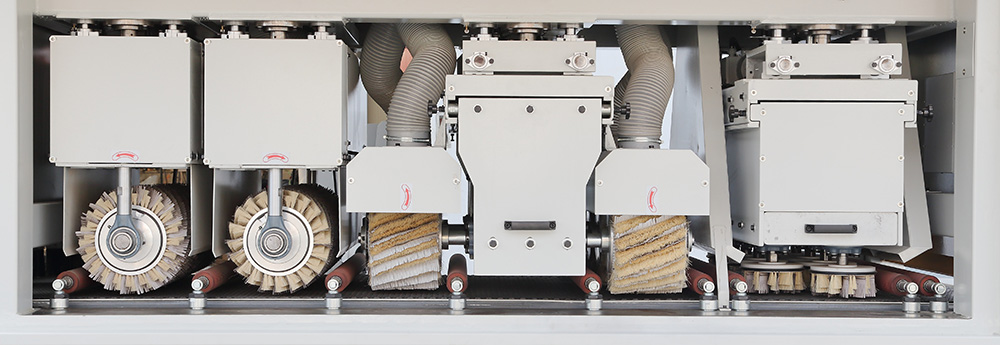

Brush Sanding Machine sands and polishes wooden doors, cabinet doors, shutters, furniture, picture frames, carved furniture and other parts before and after painting. Instead of labor, working time and labor are saved.

Machine Detail:

Specification:

| Model | SK1000P6 | /SK1300P6 |

| Working width | 1000mm | 1300mm |

| Min. Working length | 500mm | 500mm |

| Working thickness | 2-150mm | |

| Polishing roller speed | frequency control | frequency control |

| Feeding speed | 3-12.5m/min | 3-12.5m/min |

| Total motor power | 13.87kw | 15.47kw |

| Overall dimensions | 3650*1850*2100mm | 3650*2150*2100mm |

| Net weight | 4200KG | 4600KG |

The function of the Brush Sanding Machine is to remove burrs, oil stains and other surface contaminants on the surface of the white blank. Reduce the surface roughness of the workpiece, remove the various processing traces left on the surface during mechanical or manual processing, and obtain a smooth and even coating surface to enhance the mechanical adhesion of the paint for smooth polishing work. Eliminate the rough and uneven convex parts of the sealing coating and reduce the paint consumption during the sealing coating.

Precautions for the use of Brush Sanding Machine:

1. The sanding disc, grinding wheel, belt, and polishing wheel of the Brush Sanding Machine may break and explode at any time during operation. You must wear glasses, helmets and other corresponding protective equipment during operation.

2. When the machine is running, it is strictly forbidden to touch the abrasive belt, grinding wheel, grinding head, polishing wheel, etc. with hands and feet.

3. Machines without effective protection measures cannot be used.

4. A large amount of dust will be generated during sanding, so wear a mask to use.

5. The sanding equipment should be installed in a dry, ventilated place without direct sunlight.

6. When the automatic sander is used, there must be matching dust removal equipment, otherwise it is very easy to malfunction, damage the equipment, and affect production.

7. The machine needs regular maintenance.We’ll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for Original Factory China High Quality Automatic Sanding Machine, We’ve been sincerely searching forward to cooperate with prospects all over the environment. We imagine we are able to satisfy with you. We also warmly welcome consumers to go to our manufacturing unit and purchase our solutions.

Original Factory China Wood brush sanding machine, CNC brush sanding machine, With nearly 30 years’ experience in business, we have been confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.