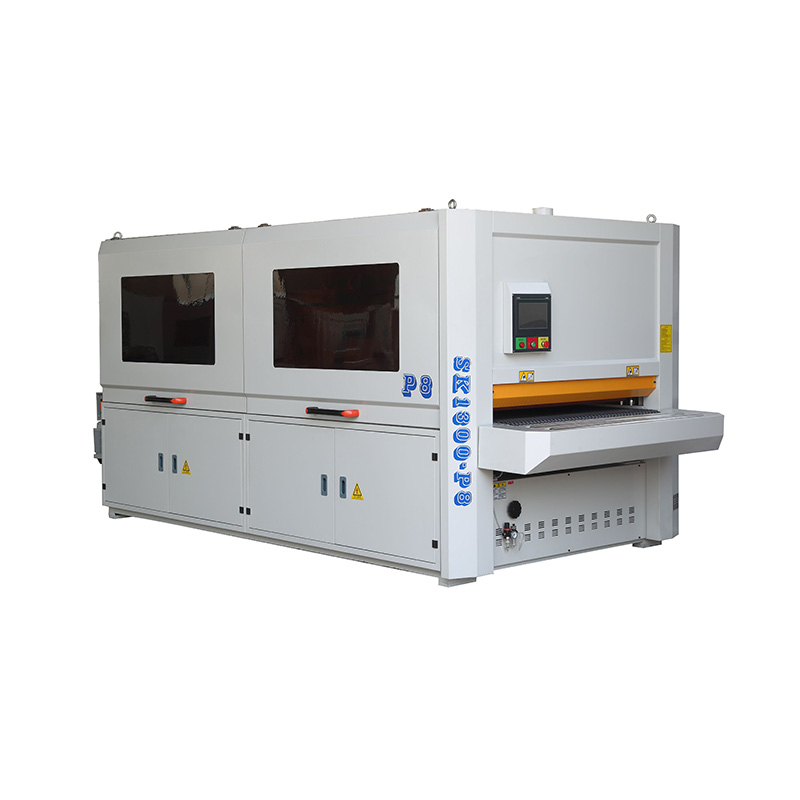

OEM/ODM China Hinge Boring Machine - Woodworking Milling Machine – Gladline

OEM/ODM China Hinge Boring Machine - Woodworking Milling Machine – Gladline Detail:

Specification:

| Working table size | 1130*670 mm |

| Max. working thickness | 120 mm |

| Spindle diameter | φ35mm |

| Spindle speed | 8000/10000 rpm |

| Power | 3/4/5.5kw |

The cutters of the vertical Woodworking Milling Machine are mounted on a vertical milling cutter shaft protruding from a fixed worktable, and the milling cutter shaft can be tilted and adjusted up and down. The work piece is close to the fixed worktable surface and the guide plate is fed manually, and the guide roller and the shaping milling fixture can also be used for the shaping milling of the side. The work piece can also be clamped on the movable worktable to process the tenon and end face. The cutter shaft of the wood mold milling machine is installed in the front part of the cantilever and can be rotated at an angle in the vertical plane. The cantilever can be raised and lowered on the column. The workpiece is clamped on the worktable and can be used for longitudinal, transverse and rotary feed. Wood mold milling machine is mainly used for model processing.

Structural features

1. The main components such as the worktable, headstock, body, middle sliding seat, base, and lifting sliding seat are all cast with high-strength materials and undergo artificial aging treatment to ensure the long-term stability of the machine tool.

2. The vertical milling head expands the processing range of the machine tool. The main shaft bearing is a tapered roller bearing, which has a strong load-bearing capacity, and the main shaft adopts energy-consumption braking, which has a large braking torque and stops quickly and reliably.

3. The feed speed can meet different processing requirements. The rapid feed can make the workpiece quickly reach the processing position, processing is convenient and fast, and the non-processing time is shortened.

4. The lubrication device can lubricate the lead screw and guide rail, which can reduce the wear of the machine tool and ensure the efficient operation of the machine tool.

5. The design of the machine tool conforms to the principle of ergonomics and the operation is convenient. The operation panels are all designed with visual symbols, which is simple and intuitive.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for OEM/ODM China Hinge Boring Machine - Woodworking Milling Machine – Gladline, The product will supply to all over the world, such as: London, Guatemala, Costa Rica, we've got all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.