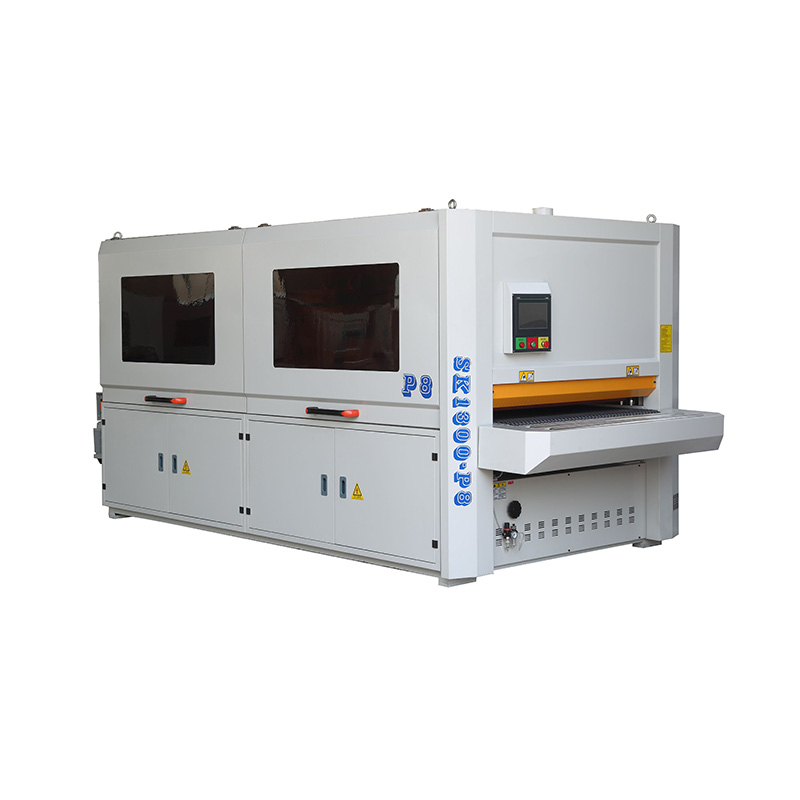

OEM Sliding Panel Saw Machine - Woodworking Precise Panel Saw GP6132AD – Gladline

OEM Sliding Panel Saw Machine - Woodworking Precise Panel Saw GP6132AD – Gladline Detail:

Precise Panel Saw is used for cutting wood structures such as density board, particle board, ABS board, PVC board, plexiglass, solid wood, and boards with similar hardness.

Machine Detail:

Specification:

| Machine Group | Precise Panel Saw |

| Dimension of sliding table | 3200×380 mm |

| Gross cut capacity | 3200 mm |

| Width of cut between saw blade and rip fence | 1250 mm |

| Tilting saw group | 0-45° |

| Diameter of main saw blade | 300 mm |

| Max cutting height (90°) | 70 mm |

| Speed of main saw spindle | 4000/6000 r.p.m |

| Main saw motor power | 5.5 kw |

| Main spindle diameter | 30 mm |

| Diameter of scoring saw blade | 120 mm |

| Speed of scoring saw spindle | 8500 r.p.m |

| Scoring saw motor power | 1.1 kw |

| Scoring saw spindle diameter | 20 mm (Φ120mm) |

| Machine Size | 3250*3450*900mm |

| Net weight | 850 KG |

| Gross Weight With Wooden Box | 900 KG |

Precise Panel Saw Instruction:

Precision panel saw are all dynamically balanced or statically balanced. Under normal circumstances, they don’t need foundation and can be added on a flat ground. During the processing operation, the workpiece is placed on the mobile worktable, and the mobile worktable is manually pushed to make the workpiece realize the feed motion. The operation is very convenient, and safety should always be paid attention to when maneuvering and flexible operation to prevent accidents. The equipment should be maintained regularly. According to the workload, dust removal work should be carried out on the inside of the machine regularly to ensure the normal heat dissipation of the motor. Dust the track of the sliding table regularly to ensure the smooth operation of the sliding table. Check the belt regularly and replace it in time if it is found to be worn. Regularly inject oil into the parts of the fuselage that need to be lubricated to ensure the stable and quiet operation of the equipment.

Product detail pictures:

Related Product Guide:

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for OEM Sliding Panel Saw Machine - Woodworking Precise Panel Saw GP6132AD – Gladline, The product will supply to all over the world, such as: Romania, Yemen, Portland, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, let us work together to get success.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!