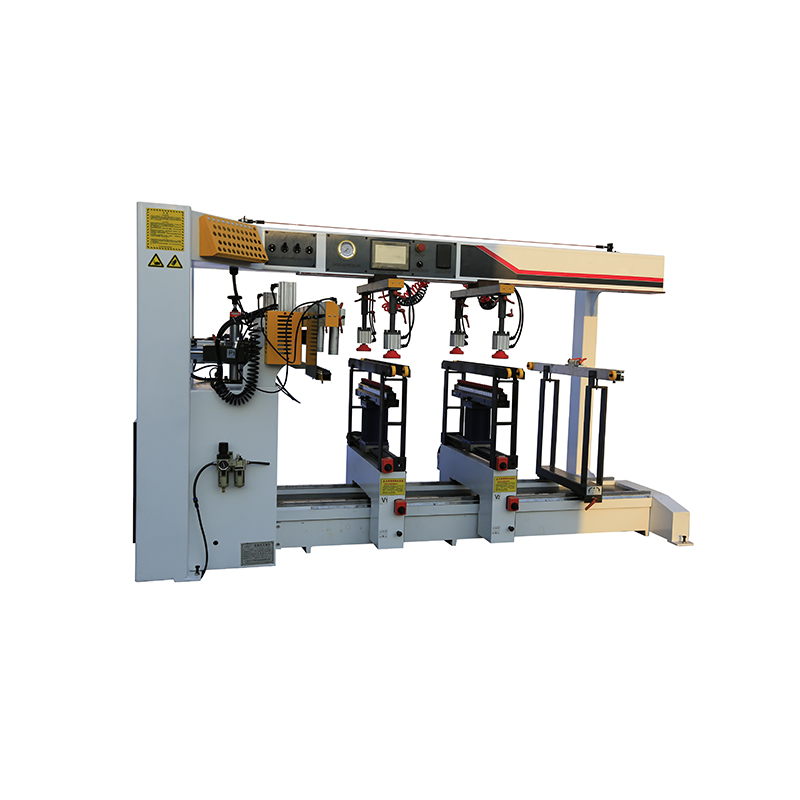

Hot New Products Multiple Spindle Drilling Machine - Triple-row Drilling Machine – Gladline

Hot New Products Multiple Spindle Drilling Machine - Triple-row Drilling Machine – Gladline Detail:

Woodworking Drilling Machine is a multi-hole processing machines with multiple drill bits and can work together. There are single-row, three-row, six-row and so on. Drilling Machine converts the traditional manual row drilling action into a mechanical action, which is automatically completed by the machine.

Specification:

| Max. diameter of holes | 35 mm |

| Depth of drilled holes | 0-60 mm |

| The number of spindles | 21*3 |

| Center distance between spindles | 32 mm |

| Rotation of spindle | 2840 r/min |

| Total motor size | 4.5 kw |

| Suitable voltage | 380 v |

| Air pressure | 0.5-0.8 Mpa |

| Gas consumption for drilling ten panels per minutes approximately | 20L/min Approximately |

| Max. distance of the two longitudinal heads | 1850 mm |

| Height of working platform off the ground | 800 mm |

| Over size | 2600x2600x1600 mm |

| Packing size | 2700x1350x1650 mm |

| Weight | 1260 kg |

In order to ensure the drilling accuracy and product quality, the drilling of panel furniture parts is generally done with multiple rows of Drilling Machine. The drill bit spacing on the multi-row drill is 32mm. Only a few countries use other modulus drill bit spacing, usually horizontal drill seats are arranged in a whole row. The straight drill seat is composed of two independent rows of seats. The number of rows of drill seats for multi-row drills is generally from 3 rows to 12 rows (additional drill seats can be added when special needs) are usually composed of horizontal drill seats and lower vertical drill seats. If there are special requirements or the number of rows of seats is large, vertical drill seats with upper and lower configurations can also be used. This should be based on production needs and processing accuracy requirements. The number of common multi-row Drilling Machine seats in production is 3 rows, 6 rows, etc.

Woodworking Drilling Machine Instruction:

1. Clean the machine table in time after the work is completed,

2. Clean up the wood chips on the guide rail and the side to prevent the jamming of the machine due to the interference of the chips.

3. Regularly clean the lead screw to prevent foreign matter from sticking to the lead screw. The lead screw is the top priority of the equipment, it affects the accuracy of the machine, and the lead screw plays an important role in the transmission process.

4. Clean the industrial control box regularly, dust is the biggest killer of drilling.

5. Dust removal and oil filling work should be carried out on the sliding track of the drill row every week.

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for Hot New Products Multiple Spindle Drilling Machine - Triple-row Drilling Machine – Gladline, The product will supply to all over the world, such as: French, Nigeria, Spain, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.