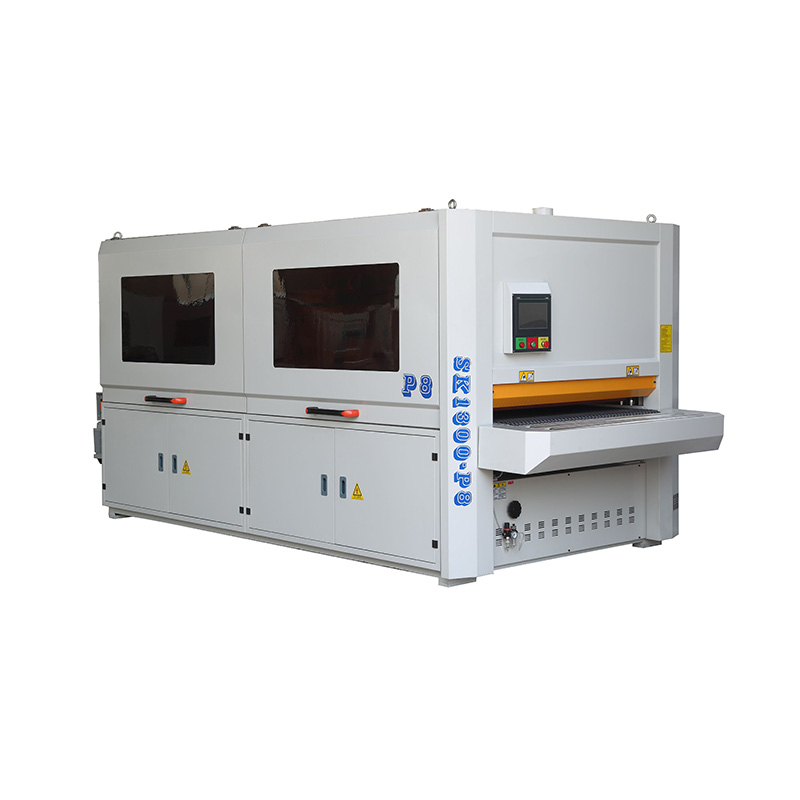

Good quality Wood Panel Saw Machine - Woodworking Precise Panel Saw GP6132S – Gladline

Good quality Wood Panel Saw Machine - Woodworking Precise Panel Saw GP6132S – Gladline Detail:

Precise Panel Saw is used for cutting wood structures such as density board, particle board, ABS board, PVC board, plexiglass, solid wood, and boards with similar hardness.

Machine Detail:

Specification:

| Machine Group | Precise Panel Saw |

| Dimension of sliding table | 3200×380 mm |

| Gross cut capacity | 3200 mm |

| Width of cut between saw blade and rip fence | 1250 mm |

| Tilting saw group | 0-45° |

| Diameter of main saw blade | 300 mm |

| Max cutting height (90°) | 70 mm |

| Max cutting height (45°) | 55mm |

| Speed of main saw spindle | 4000/6000 r.p.m |

| Main saw motor power | 5.5 kw |

| Main spindle diameter | 30 mm |

| Diameter of scoring saw blade | 120 mm |

| Speed of scoring saw spindle | 8000 r.p.m |

| Scoring saw motor power | 1.1 kw |

| Scoring saw spindle diameter | 20 mm (Φ120mm) |

| Machine Size | 3250*3150*900mm |

| Net Weight | 860 KG |

| Gross Weight with Wooden Box | 900 KG |

Sliding Table Saw Machine Instruction:

1. The operator should strictly observe the lubrication parts of the Sliding Table Saw to maintain, lubricate and sanitize the machine, and keep the equipment lubricated and clean.

2. Check, clean, maintain and refuel the workpiece.

A: Clean the sawdust inside and outside the machine tool every day and clean it up with an air gun.

B: Use an air gun to clean the sliding table every day, and remove the fallen wood and dust.

C: If the guide rail of the sliding table is soiled by resin, gasoline should be used for cleaning, and sponge can be used if necessary, and bristles or sandpaper should not be used. This will damage the guide rail and make it difficult to repair.

D: Clean the guide rail and lubricate it.

E: Clean up the wool of the dust collecting tank and keep the dust suction unobstructed.

F: Check the tightness of the drive belts of the main and auxiliary saws and adjust them appropriately.

G: The main bearing, linear sliding block and electrical components should avoid blowing with high air guns to avoid damage to the components.

H: Always keep the machine tidy and clean the whole machine with an air gun when off work.

3. Anti-rust and lubrication treatment of the machine.

A: A little anti-rust oil should be applied to the exposed metal surface every week to prevent rust and maintain lubricity.

B: Fill the main saw spindle bearing and auxiliary saw spindle bearing with high-speed lubricating grease, use a grease gun, and fill it regularly once a month.

C: The saw base lifting turbine box needs to be lubricated, and the oil is regularly changed once a year. The professional maintenance of the Sliding Table Saw needs to be professional by the equipment department

Product detail pictures:

Related Product Guide:

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for Good quality Wood Panel Saw Machine - Woodworking Precise Panel Saw GP6132S – Gladline, The product will supply to all over the world, such as: Sacramento, Vietnam, French, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.