Good Quality Glue Spreading Machine - Vacuum Laminating Machine – Gladline

Good Quality Glue Spreading Machine - Vacuum Laminating Machine – Gladline Detail:

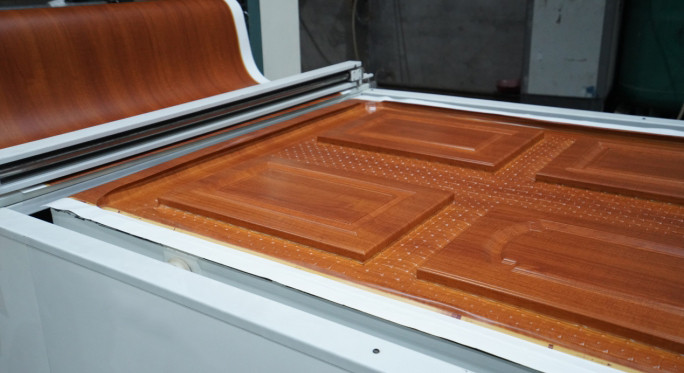

The Vacuum Laminating Machine adopts far-infrared heating and vacuum suction veneer technology, which can quickly paste PVC wood grain decorative sheets, regardless of plane, curved surface, more modeling, complex structure and special-shaped components can complete the surface and side bonding at one time. After veneer, the product has elegant finishes, rich patterns, no color difference on the surface, high smoothness, waterproof and moisture-proof, and firm bonding. After veneer, it is smooth and bright without painting. It not only eliminates the pollution of harmful substances in the paint to the human body and the environment, but also It saves paint cost and labor, and shortens the production period, so that the product truly becomes a high-end, affordable, healthy and comfortable new green environmental protection decorative material.

Specification:

| Work table size | 2500*1300(1100)*60mm |

| Total power | 30kw |

| Actual power consumption | 10kw |

| Ultimate vacuum | -0.1Mpa |

| Machine size | 9200*1500*1500mm |

The Vacuum Laminating Machine is to absorb heat and plasticize PVC thermoplastic plastic coils (PVC film), leather, veneer, etc. on MDF, stone and other boards, and produce high-quality cabinet doors, wardrobe doors, sliding doors, The machine for photo frames and other products, the principle of the blister machine, the forming process is mainly to use the vacuum suction generated by the vacuum pump to vacuum the softened PVC thermoplastic plastic coil into sheets of different shapes. The product specifications are highly adaptable and different in large, medium and small. Both thick and thin products can be made by blister molding. The sheet can be as thin as 5mm or even thinner. The product area can be as large as 1.22×2.44㎡, as small as the finger width.

The Vacuum Laminating Machine has a wide range of applications, such as cupboard door blister, wardrobe door blister, sliding door blister, swing door blister, paint-free door blister, molded door blister, photo frame blister, computer desk blister, massage chair blister Plastic, tea cabinet blister, hot pot table blister, leather soft bag blister, veneer veneer blister, stone PVC blister, etc., less investment in equipment, more PVC film patterns, paint-free green and pollution-free, especially suitable for whole-house customization , The production power is higher.

Product detail pictures:

Related Product Guide:

We take pleasure in a really excellent name amongst our shoppers for our exceptional product or service excellent, competitive rate and also the greatest services for Good Quality Glue Spreading Machine - Vacuum Laminating Machine – Gladline, The product will supply to all over the world, such as: Buenos Aires, Congo, Mexico, We always hold on the company's principle "honest, professional, effective and innovation", and missions of: let all drivers enjoy their driving at night, let our employees can realize their value of life, and to be stronger and service more people. We are determined to become the integrator of our product market and one-stop service provider of our product market.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.