Edgeband Machine Suppliers - Automatic Edge Banding Machine GE320D – Gladline

Edgeband Machine Suppliers - Automatic Edge Banding Machine GE320D – Gladline Detail:

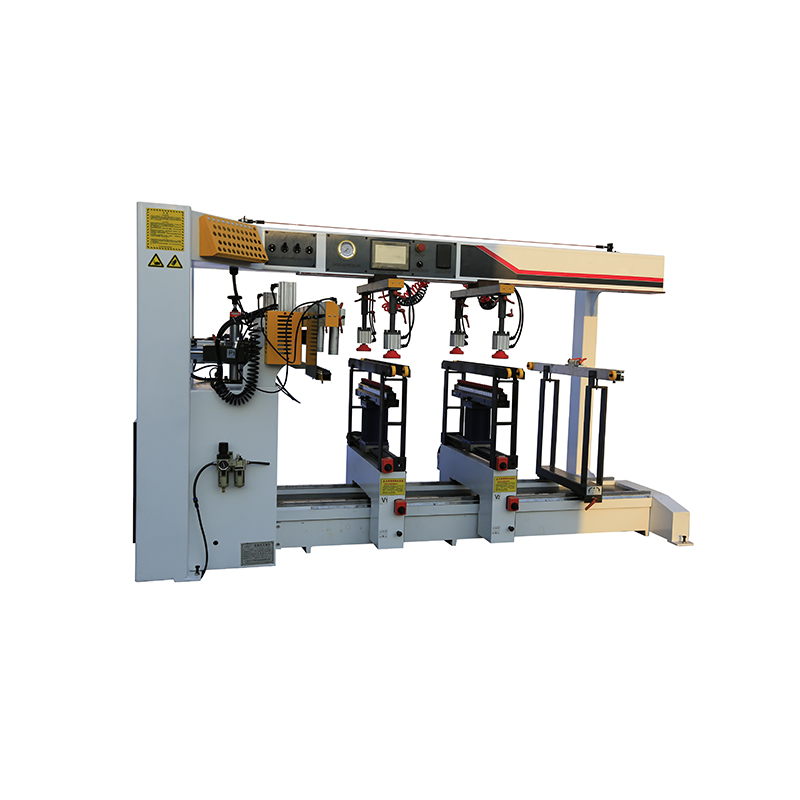

Automatic Edge Banding Machine GE320D can perform straight edge banding.

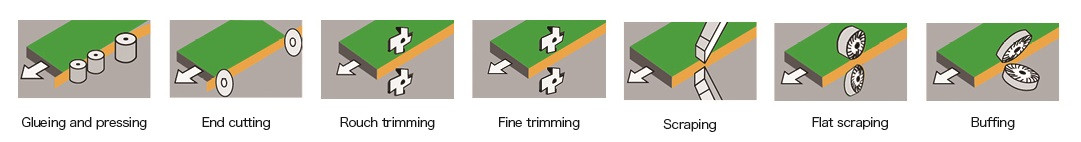

Function is as below:

Machine Detail:

Edge bander is a necessary machine for plate-type furniture production.

It is suitable for straight edge banding and trimming of medium density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc.

Specification:

| Machine Group | Automatic Edge Banding Machine |

| Function | Gluing and Press->End Cutting->Rough Trimming->Fine Trimming->Scraping->Flat Scraping->Buffing |

| Total Power | 6.3KW |

| Feeding Speed | 15-23m/min |

| Edge Band Thickness | 0.4-3mm |

| Panel Thickness | 10-60mm |

| Panel Length | ≥150mm |

| Panel Width | ≥40mm |

| Work air pressure | 0.6Mpa |

| Min panel size (L*W) | 350*40mm, 150*150mm |

| Weight | 1000kg |

| Machine Size | 3938*830*1610mm |

Machine Instruction:

1. Before using, we must first understand the Automatic Edge Bander.

2. The specific steps of using the fully automatic edge banding machine:

①Check the inside and outside of the equipment before use.

②The Automatic Edge Bander is turned on after checking it is correct before use.

③Wait for the machine to work after it is heated, but control the temperature when using it.

④ After use, shut down for cleaning and inspection.

4. The cleanliness of the equipment is the guarantee for our smooth work. If there is debris, it will not only affect the comfort of the Automatic Edge Bander during use, but also cause other losses due to some unexpected situations.

5. Check the usage of the edge banding glue of the equipment, mainly for the control and adjustment of the edge banding glue. This is related to the basic usage of the Automatic Edge Bander.

6. Clean the equipment regularly, because a lot of dirt will accumulate in the equipment for a long time. Over time, it will block the equipment and fail to start.

8. Keep the temperature in the workshop of the Automatic Edge Bander:

The temperature of the Automatic Edge Bander should not be too high or too low during the working process. Too low temperature will cause the oil to freeze and the machine cannot operate normally, and too high temperature will easily cause inconvenience of heat removal and cause damage to the motor.

9. Operate strictly in accordance with the equipment manual.

10. We should check the parts of the Automatic Edge Bander during or after using the automatic edge banding machine.

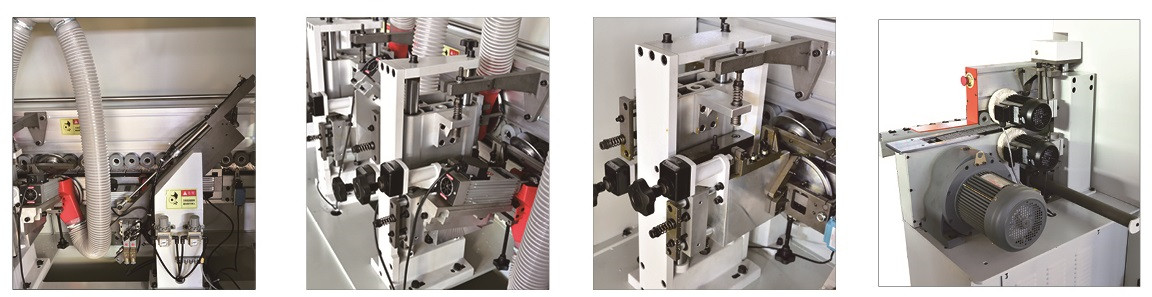

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for Edgeband Machine Suppliers - Automatic Edge Banding Machine GE320D – Gladline, The product will supply to all over the world, such as: Bolivia, Frankfurt, Ukraine, We have to continue to uphold the "quality, comprehensive, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class products and improve service welcome overseas customers patrons.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!