Discount Woodworking Manual Edge Banding - Automatic Edge Banding Machine GE468 – Gladline

Discount Woodworking Manual Edge Banding - Automatic Edge Banding Machine GE468 – Gladline Detail:

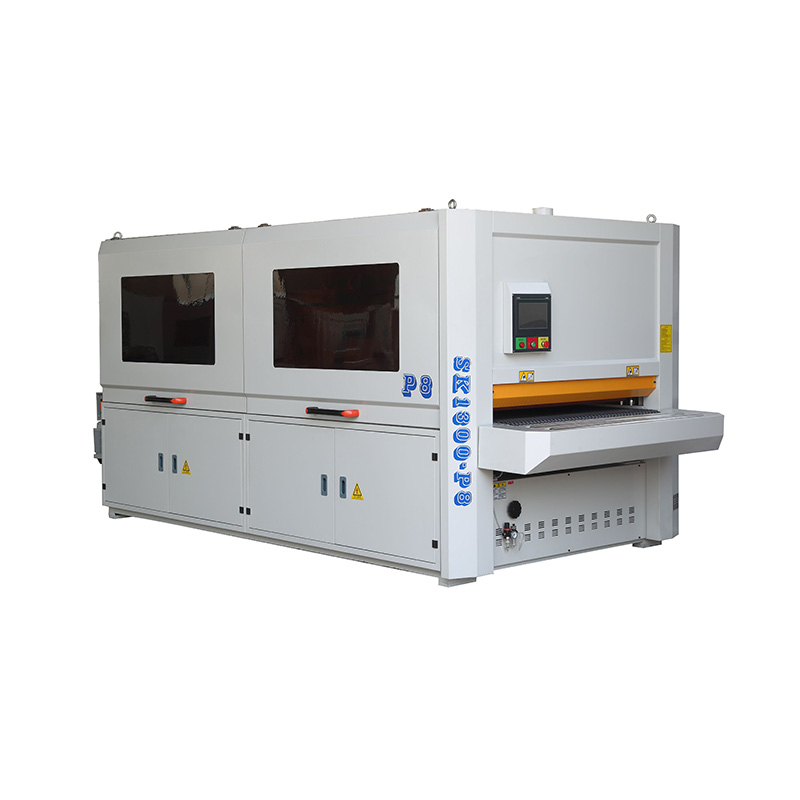

Automatic Edge Banding Machine GE360D can perform straight edge banding.

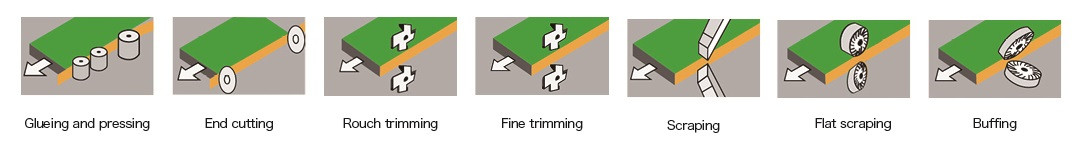

Function is as below:

Machine Detail:

Edge bander is a necessary machine for plate-type furniture production.

It is suitable for straight edge banding and trimming of medium density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc.

Specification:

| Machine Group | Automatic Edge Banding Machine |

| Function | Gluing and Press->End Cutting->Rough Trimming->Fine Trimming->Scraping->Flat Scraping->Buffing |

| Total Power | 11KW |

| Feeding Speed | 15-23m/min |

| Edge Band Thickness | 0.4-3mm |

| Panel Thickness | 10-60mm |

| Panel Length | ≥150mm |

| Panel Width | ≥60mm |

| Work air pressure | 0.6Mpa |

| Min panel size (L*W) | 300*60mm, 150*150mm |

| Weight | 2090kg |

| Machine Size | 5659*830*1610mm |

With the development of the construction industry, more and more people use the fully Automatic Edge Banding Machine for floor stitching, which is more complete and convenient than the traditional manual process. Here is an introduction to its use and characteristics:

1. The Automatic Edge Banding Machine is a new, sophisticated, high-efficiency linear Edge Banding Machine, which is deeply favored by woodworking furniture manufacturers.

2. The structure is compact, the layout is reasonable, and the appearance is beautiful; it adopts sound insulation, dust collection port, and anti-overload devices.

3. The Automatic Edge Banding Machine is mainly suitable for the straight edge banding of plywood, fiberboard, particle board and other sections.

4, with edge band tray device, preheating device, gluing device, welting device, finishing device, scraping device, polishing device, automatic aligning and other working units.

5. High-performance electrical appliances are used to control high-performance, and frequency converters are used to control high-speed motors.

6. The Automatic Edge Banding Machine adopts a good pressure regulating valve to control the air flow, so that each workpiece is processed and assembled more accurately. Each process is inspected according to the strict technical requirements.

7. The Automatic Edge Banding Machine adopts a heavy-duty drag motor, which has a strong drag force that is stable and durable.

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for Discount Woodworking Manual Edge Banding - Automatic Edge Banding Machine GE468 – Gladline, The product will supply to all over the world, such as: Florence, Malta, Melbourne, We have customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, don't hesitate to contact us.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.