Discount Woodworking Edge Banding Machinery - Automatic Edge Banding Machine GE368 – Gladline

Discount Woodworking Edge Banding Machinery - Automatic Edge Banding Machine GE368 – Gladline Detail:

Automatic Edge Banding Machine is one of the equipment that the panel furniture manufacturers will purchase, and it is an indispensable equipment in the panel furniture production line.

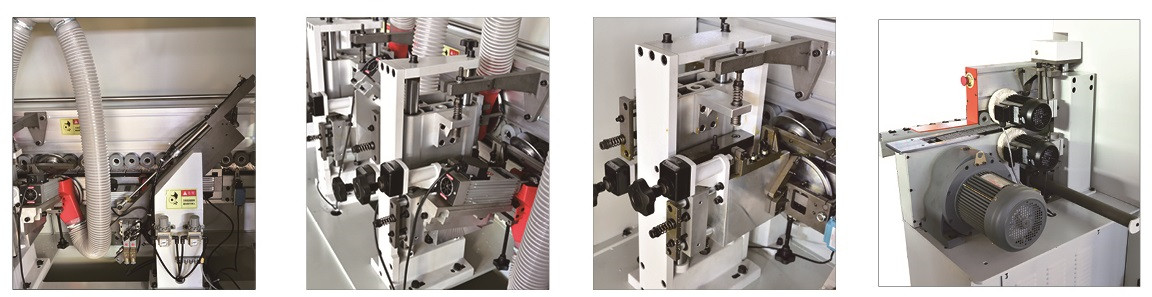

Machine Detail:

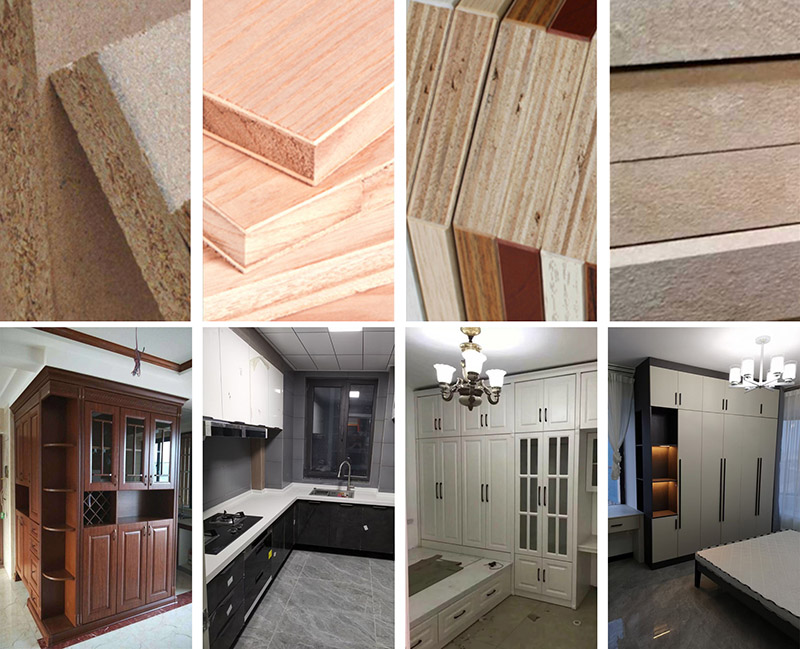

Edge bander is a necessary machine for plate-type furniture production.

It is suitable for straight edge banding and trimming of medium density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc.

Specification:

| Machine Group | Automatic Edge Banding Machine |

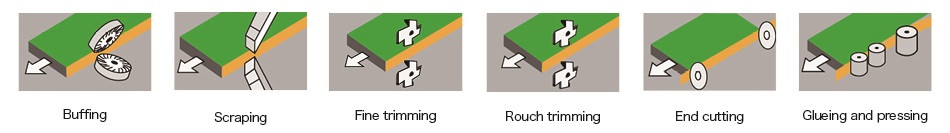

| Function | Gluing and Press->End Cutting->Rough Trimming->Fine Trimming->Scraping->Buffing |

| Total Power | 10.4KW |

| Feeding Speed | 15-23m/min |

| Edge Band Thickness | 0.4-3mm |

| Panel Thickness | 10-60mm |

| Panel Length | ≥150mm |

| Panel Width | ≥40mm |

| Work air pressure | 0.6Mpa |

| Min panel size (L*W) | 350*40mm, 150*150mm |

| Weight | 1495kg |

| Machine Size | 4417*830*1610mm |

The Edge Banding Machine can perform linear edge banding, trimming and polishing on furniture panels with high precision and efficiency. However, many people ignore the maintenance of the Edge Banding Machine in the process of using the edge banding machine. Although the maintenance of the Edge Banding Machine may consume a certain amount of manpower and material resources, it can extend the service life of the Edge Banding Machine and improve work efficiency. Therefore, the maintenance of the edge banding machine is very important. Next, I will introduce to you the four major aspects of the maintenance of the Edge Banding Machine.

1. Clean up regularly. First of all, we must clean up the wood chips and various wood debris generated during the production process of the Edge Banding Machine to prevent the accumulation of wood from causing the machine to jam, which affects the normal use of the Edge Banding Machine. Secondly, it is necessary to clean up some stains on the surface of the machine in time to keep the Edge Banding Machine clean. It is tidy and prevents harmful substances from corroding and damaging the surface of the edge-sealing fuselage.

2. Lubricate the Edge Banding Machine regularly. Lubricating oil should be added to the bearings of each part of the edge banding machine on a regular basis, and an appropriate lubricant must be selected, otherwise it will also affect the normal use of the Edge Banding Machine.

3. Regular inspections. The Edge Banding Machine should be inspected and maintained regularly. During the maintenance process, some wear conditions of the gears, bearings and other parts of the Edge Banding Machine should be carefully checked, and the severely worn parts should be replaced in time.

4. The computer system maintenance of the Edge Banding Machine. Today’s Edge Banding Machine is mostly connected to a computer, so as to realize the automatic operation of computer programming. If there is a problem with the computer system, it will also affect the normal use of the machine.

Application:

Advantage:

●The edge banding machine body is made of 18mm national standard high-strength steel plate, exclusive welding technology, box-type body structure, after high temperature quenching treatment, it is not easy to be deformed for a long time, and the heavy-duty gantry machining center is processed in one time. The flatness is extremely high!

●Conveyor belt guide rails are made of bearing steel, chrome-plated, wear-resistant and not easy to rust, high straightness, low friction coefficient, and stable conveying at a uniform speed!

●The conveying motor adopts customized models, high power, stable power output, and has a thermal protection system to increase the safety factor!

●The high-speed motor, full-head guide rail, pneumatic system, air cylinder, safety valve and frequency converter all adopt well-known brands. Highly sensitive Airtac magnetic switch and high flexible shielded cable.

●Automatic air return solenoid valve to ensure the stability of 5 million operations. Equipped with air pressure stabilization control to ensure continuous and stable machine action in all aspects!

●The edge banding machine body is processed and formed by CNC machining center at one time and is assembled with imported bearings with an error of 0.05mm to ensure smooth and smooth overall trimming effect.

●The edge banding machine body is laser cut, the surface is flat, no indentation, no burrs, and high dimensional accuracy. All machine parts are processed by imported CNC, with high precision, ensuring long service life and precise operation of the parts!

●The conveyor chain block is made of high-quality silica gel by one-time die-casting, and its wear resistance meets international standards, and it is smooth and non-jumping. Ensure that the edge banding machine achieves good stability.

FAQ:

Q1: Are you a factory?

A: We are a specialized woodworking machinery manufacturer

Q2: Can I make an OEM order?

A: Yes, we accept OEM and customized

Q3: How do I do the installation of the edge banding machine?

A: We provide installation guide for you and if it is necessary, we will send our installation team to job site.

Q4: Do you have a MOQ?

A: 1 set

Q5: How long is the warranty?

A: 1 year

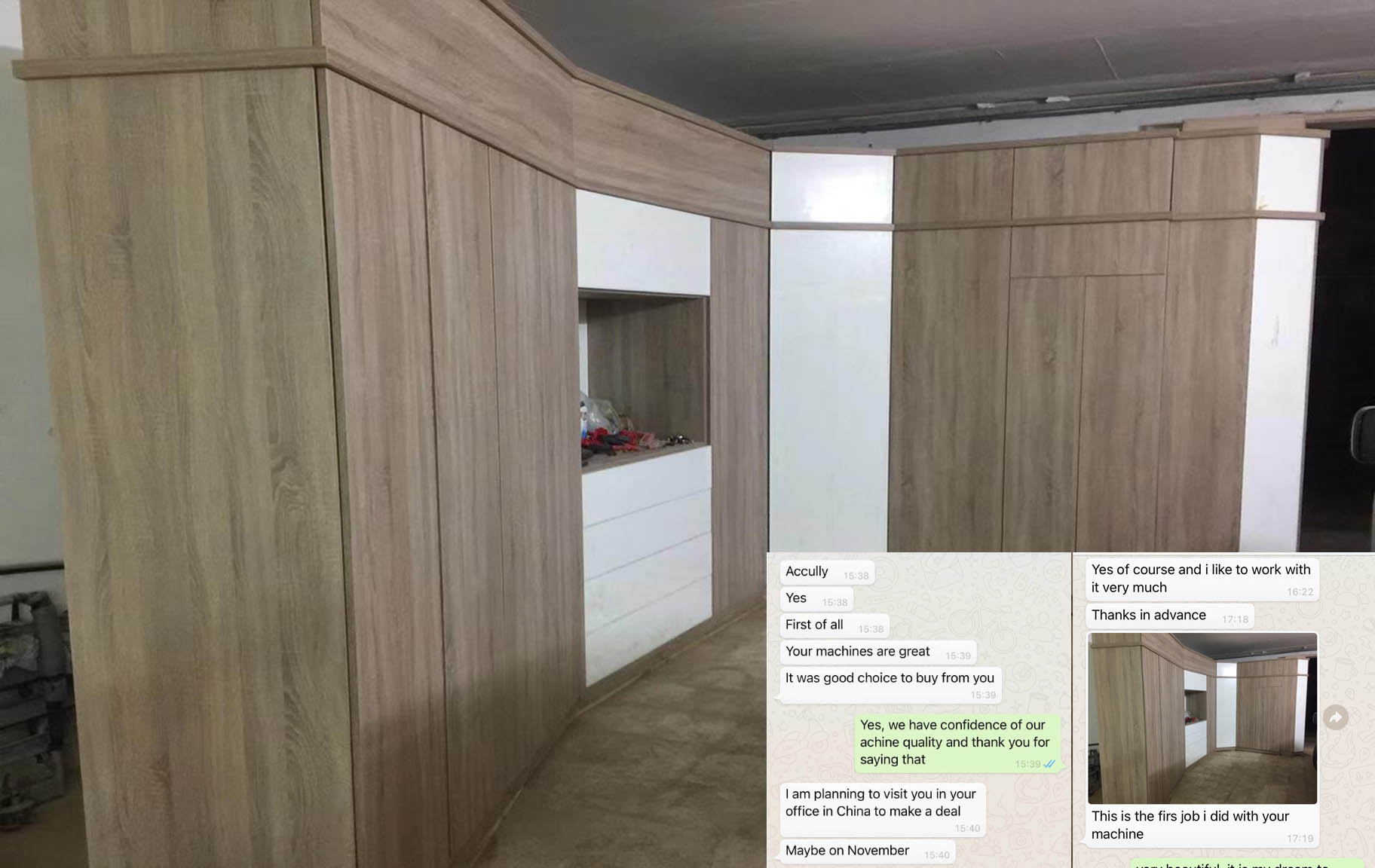

Customer Feedback:

Package:

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Discount Woodworking Edge Banding Machinery - Automatic Edge Banding Machine GE368 – Gladline, The product will supply to all over the world, such as: Nairobi, Doha, Japan, We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!