2021 Good Quality Edge Banding Machinery - Automatic Edge Banding Machine GE365 – Gladline

2021 Good Quality Edge Banding Machinery - Automatic Edge Banding Machine GE365 – Gladline Detail:

Automatic Edge Banding Machine GE365 can perform straight edge banding.

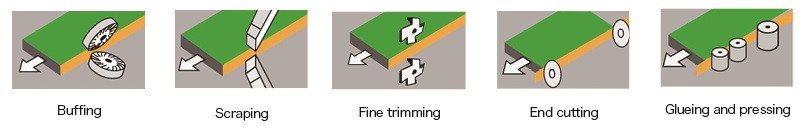

Function is as below:

Machine Detail:

Edge bander is a necessary machine for plate-type furniture production. It is suitable for straight edge banding and trimming of medium density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc.

Specification:

| Machine Group | Automatic Edge Banding Machine |

| Function | Gluing and Press->End Cutting->Fine Trimming->Scraping->Buffing |

| Total Power | 8.3KW |

| Feeding Speed | 15-23m/min |

| Edge Band Thickness | 0.4-3mm |

| Panel Thickness | 10-60mm |

| Panel Length | ≥150mm |

| Panel Width | ≥40mm |

| Work air pressure | 0.6Mpa |

| Min panel size (L*W) | 350*40mm, 150*150mm |

| Weight | 1300kg |

| Machine Size | 3938*830*1610mm |

Edge banding is an important process in the manufacturing process of panel furniture. The quality of edge banding directly affects the quality, price and grade of the product. By sealing the edges, the appearance quality of the furniture can be well improved, and the corners of the furniture can be prevented from being damaged during transportation and use, and the veneer layer is lifted or peeled off. At the same time, it can waterproof, seal the release of harmful gases and reduce deformation, etc. It can beautify the furniture and make the mood happy. The raw materials used by panel furniture manufacturers are mainly particleboard, medium-density board and other man-made boards. The main edge bands selected are PVC, polyester, melamine and wood strips.

Different materials and specifications of edge banding use different Edge Banding Machine. Nowadays, the Edge Banding Machine used by furniture manufacturers mainly include manual straight-curve Edge Banding Machine and automatic straight-line Edge Banding Machine. The manual Edge Banding Machine has a relatively simple structure, and its installation, use and maintenance are relatively easy; the fully automatic linear Edge Banding Machine has a complex structure, high manufacturing precision and high production efficiency. Customers can make a reasonable choice according to their actual needs.

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for 2021 Good Quality Edge Banding Machinery - Automatic Edge Banding Machine GE365 – Gladline, The product will supply to all over the world, such as: El Salvador, Serbia, Afghanistan, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!