2021 China New Design Manual Edge Banding Machine - Automatic Edge Banding Machine GE368 – Gladline

2021 China New Design Manual Edge Banding Machine - Automatic Edge Banding Machine GE368 – Gladline Detail:

Automatic Edge Banding Machine GE368 can perform straight edge banding.

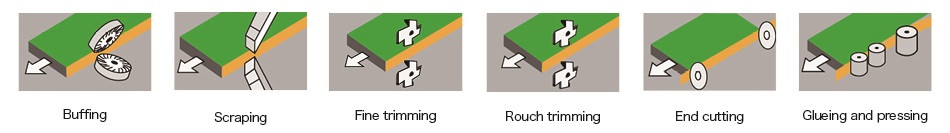

Function is as below:

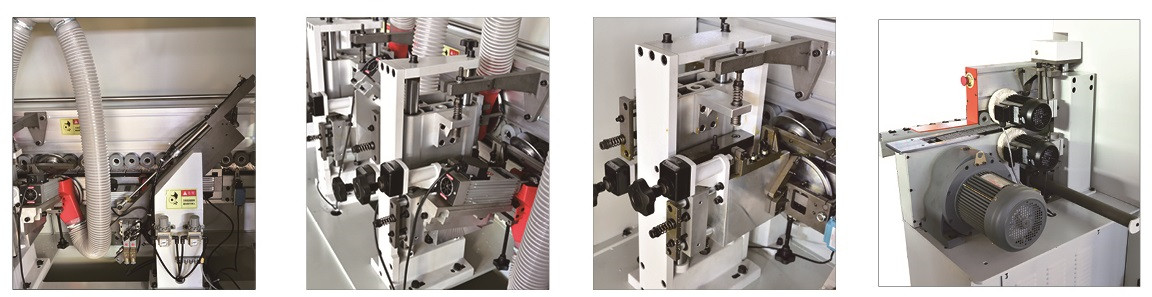

Machine Detail:

Edge bander is a necessary machine for plate-type furniture production.

It is suitable for straight edge banding and trimming of medium density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc.

Specification:

| Machine Group | Automatic Edge Banding Machine |

| Function | Gluing and Press->End Cutting->Rough Trimming->Fine Trimming->Scraping->Buffing |

| Total Power | 10.4KW |

| Feeding Speed | 15-23m/min |

| Edge Band Thickness | 0.4-3mm |

| Panel Thickness | 10-60mm |

| Panel Length | ≥150mm |

| Panel Width | ≥40mm |

| Work air pressure | 0.6Mpa |

| Min panel size (L*W) | 350*40mm, 150*150mm |

| Weight | 1495kg |

| Machine Size | 4417*830*1610mm |

The Edge Banding Machine can perform linear edge banding, trimming and polishing on furniture panels with high precision and efficiency. However, many people ignore the maintenance of the Edge Banding Machine in the process of using the edge banding machine. Although the maintenance of the Edge Banding Machine may consume a certain amount of manpower and material resources, it can extend the service life of the Edge Banding Machine and improve work efficiency. Therefore, the maintenance of the edge banding machine is very important. Next, I will introduce to you the four major aspects of the maintenance of the Edge Banding Machine.

1. Clean up regularly. First of all, we must clean up the wood chips and various wood debris generated during the production process of the Edge Banding Machine to prevent the accumulation of wood from causing the machine to jam, which affects the normal use of the Edge Banding Machine. Secondly, it is necessary to clean up some stains on the surface of the machine in time to keep the Edge Banding Machine clean. It is tidy and prevents harmful substances from corroding and damaging the surface of the edge-sealing fuselage.

2. Lubricate the Edge Banding Machine regularly. Lubricating oil should be added to the bearings of each part of the edge banding machine on a regular basis, and an appropriate lubricant must be selected, otherwise it will also affect the normal use of the Edge Banding Machine.

3. Regular inspections. The Edge Banding Machine should be inspected and maintained regularly. During the maintenance process, some wear conditions of the gears, bearings and other parts of the Edge Banding Machine should be carefully checked, and the severely worn parts should be replaced in time.

4. the computer system maintenance of the Edge Banding Machine. Today’s Edge Banding Machine is mostly connected to a computer, so as to realize the automatic operation of computer programming. If there is a problem with the computer system, it will also affect the normal use of the machine.

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for 2021 China New Design Manual Edge Banding Machine - Automatic Edge Banding Machine GE368 – Gladline, The product will supply to all over the world, such as: Bulgaria, Juventus, Puerto Rico, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.