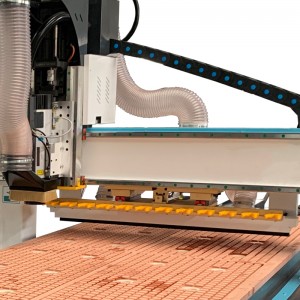

Straight line auto tool changing CNC router

Straight-line auto tool changing CNC router is a highly automated woodworking CNC router. It can change work bits automatically, save time and labor, reduce the generation of waste, and improve the utilization rate of board. The function of the straight-line auto tool changing CNC router is door panel modeling, slotting, cutting, punching, carving, etc.

Technical Data

| Work area | 1300*2500*200mm (2000*3000mm work table is optional) |

| Empty line engraving speed | 80000mm/min |

| Maximum cutting speed | 25000mm/min |

| Repeatability | ±0.02mm |

| Compatible software | AIphacam door software Yunxi Yimu Haixun 1010 etc. |

| Engraving instructions | Standard G code, u00, mmg, plt |

| Software operating environment | WIN7 64 bit |

| X, Y, Z structure | XY-axis high-precision racks are driven by GermanHenry's brand, Z-axis imported ball screw is Taiwan TPI brand |

| Control System | Taiwan Syntec 60CB six-axis control system, integrated drive and control machine. |

| Spindle motor | 9kw air-cooled motor Changzhou HQD/CC |

| Tool Magazine | 12 tools (16 tools is optional) |

| Input voltage | According to your request |

| Drive motor |

XYZ three-axis adopts Leadshine motor and supporting driver, (no need to return to the mechanical origin after power-on) Z-axis plus a brake |

| Reducer | YURNU imported from Ital/Japan Xinbao reducery, reducer plus top block |

| Transfer method | XY-axis high-precision helical rack drive imported from Germany, Germany imported Henry's brand, Z-axis Taiwan TBI screw drive |

| Frequency converter | Shanghai Fuling 11kw frequency converter double frequency converter |

| Guide | Taiwan imported square rail CSK30/Longma 30 dustproof and durable |

| Maintenance | Automatic oil injection system |

| Vacuum cleaner | Double bucket foot power 5.5kw vacuum cleaner |

| Attached | Cutting tool, Yimu software, etc. |

| Accessories | Highly flexible shielded cable, French Schneider electrical components and other imported components have stableperformance |

Our CNC router is integral steel structure, thick bed (welded by our factory) tempering and quenching treatment. First, this CNC router uses a planer for rough machining, and use a large CNC machining center for milling and CNC drilling of the guide rail table and rack surface. Heat treatment annealing, stress relief-pickling, phosphating and other surface treatment-CNC machining center milling. Cutting and drilling are formed at one time. Large steel plate gantry beam. Machining components: all processed by vertical machining center. Through the above processing, the basic accuracy of the accessories is strongly guaranteed and the wall thickness is 8 thick. The 7.5kw water-cooled vacuum pump table is a vacuum adsorption (double-layer) table, which is porous and can strongly adsorb materials of different areas.

Detail Pictures

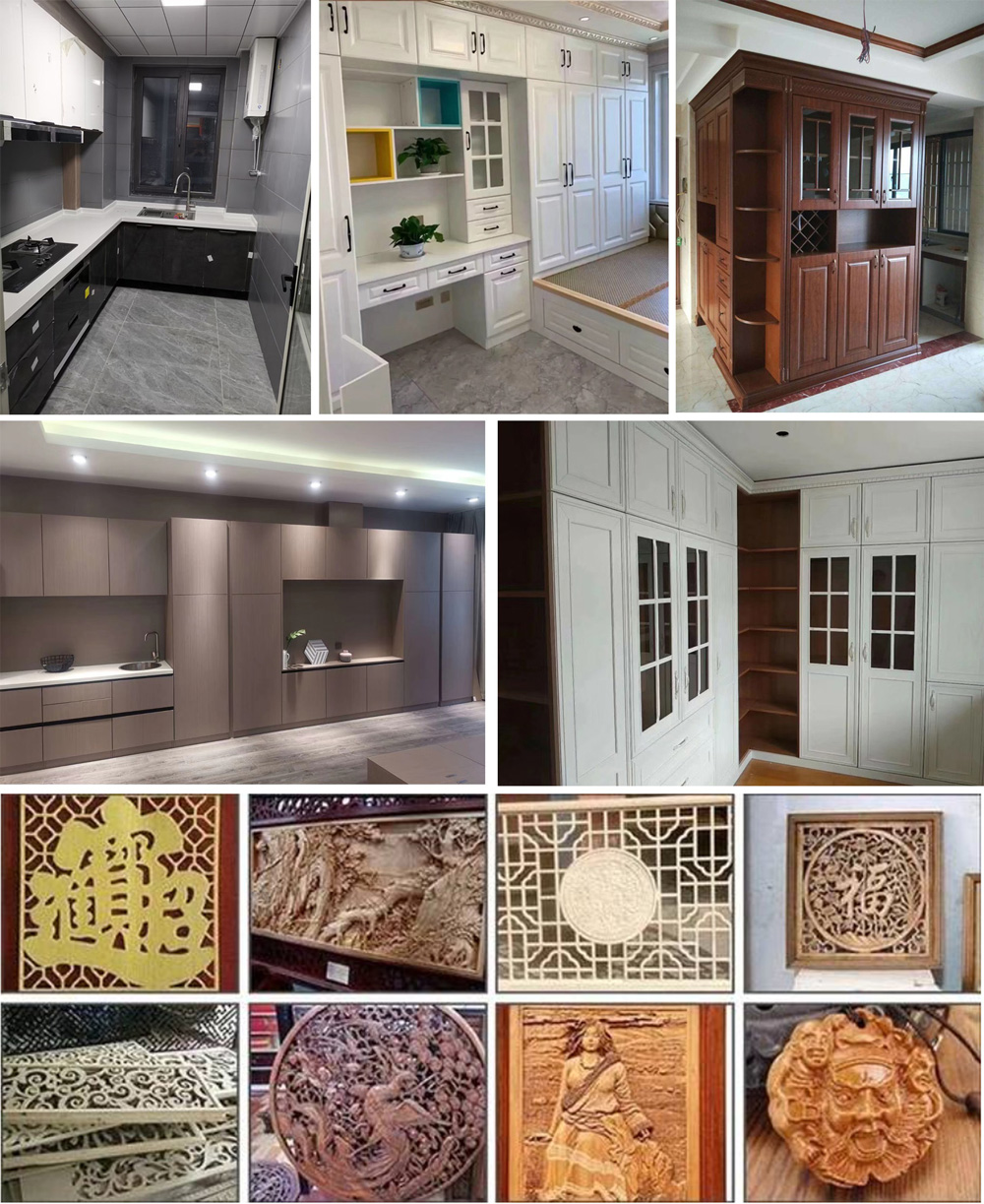

Application

Advantage

● CNC router is overall seamless big steel tube structure. Processed by high tempering treatment and reliving of internal pressure, ensure the bathe more rigidity, reliability and durability.

● CNC router uses top-quality world-famous brand components, to make the machine high-precision and high-efficiency. Top quality spindle, Delta inverter, TBI ball screw, DSP control system and so on.

● CNC router is humanized and beautiful designing. Beautiful appearances and high-quality painting make the machine beautiful and avoid rusting.

● CNC router is easy and safe operation and low maintenance cost. With memory function in case of power off. The only consumable part of the machine is the bit. Free training in our factory.

● Many optional configuration and OEM service available. We produce various machines as per your request.

FAQ

Q1: Are you a factory?

A: We are a specialized woodworking machinery manufacturer

Q2: Can I make an OEM order?

A: Yes, we accept OEM and customized

Q3: How do I do the installation of the CNC router?

A: We provide installation guide for you and if it is necessary, we will send our installation team to job site.

Q4: Do you have a MOQ?

A: 1 set

Q5: How long is the warranty?

A: 1 year

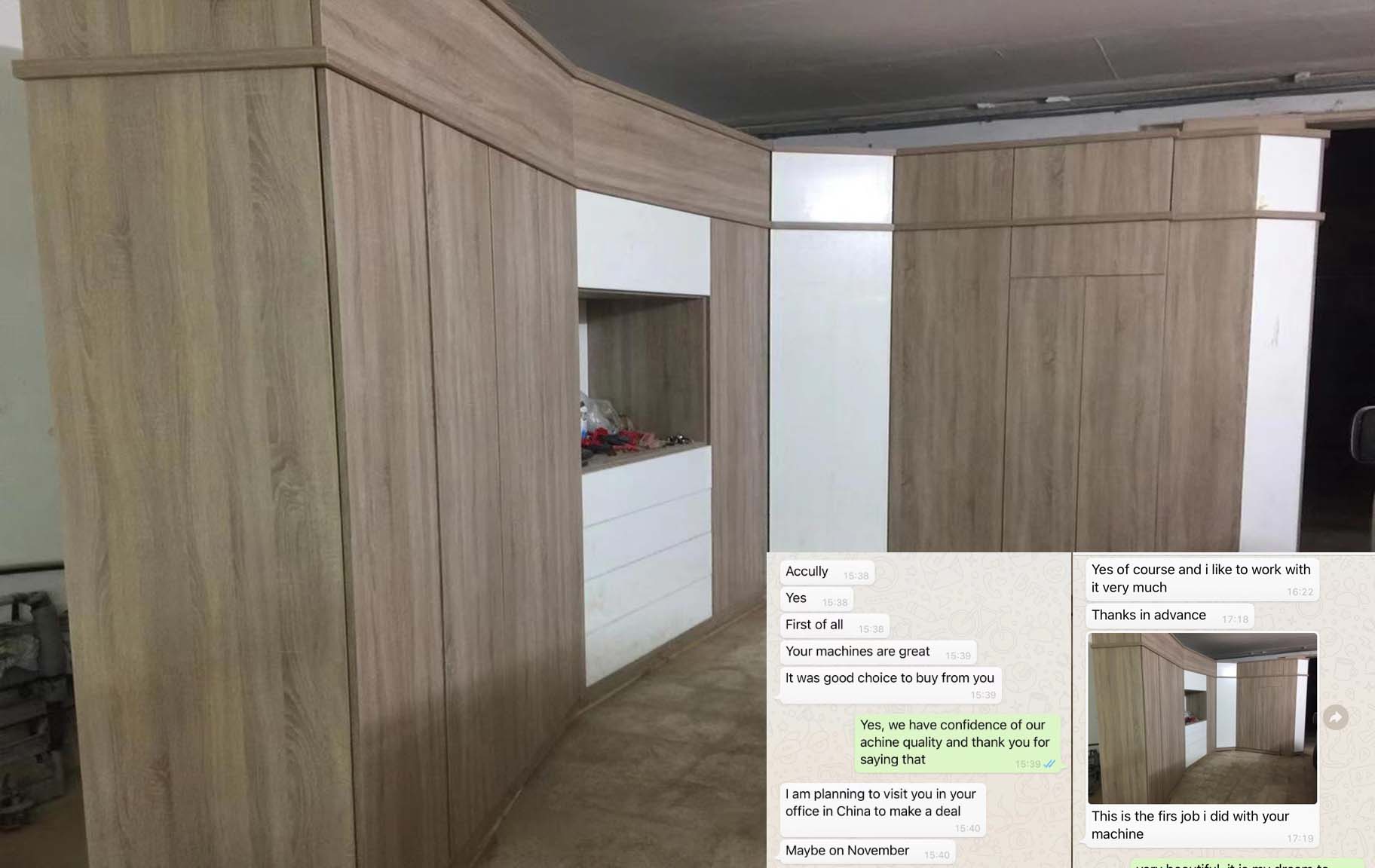

Customer Feedback

Package