CNC router is widely used in woodworking industry in recent years, it can help you significantly reduce production costs.

1. It can replace the traditional manual operation, increase material utilization! Reduce the material waste, thereby reducing the cost of materials.

2. Save labor, one person can operate multiple machines.

3. All numerical dimensions are calculated by computer with high accuracy.

4. Machine office can be suspended at any time, increase or decrease speed, adjust depth, etc.

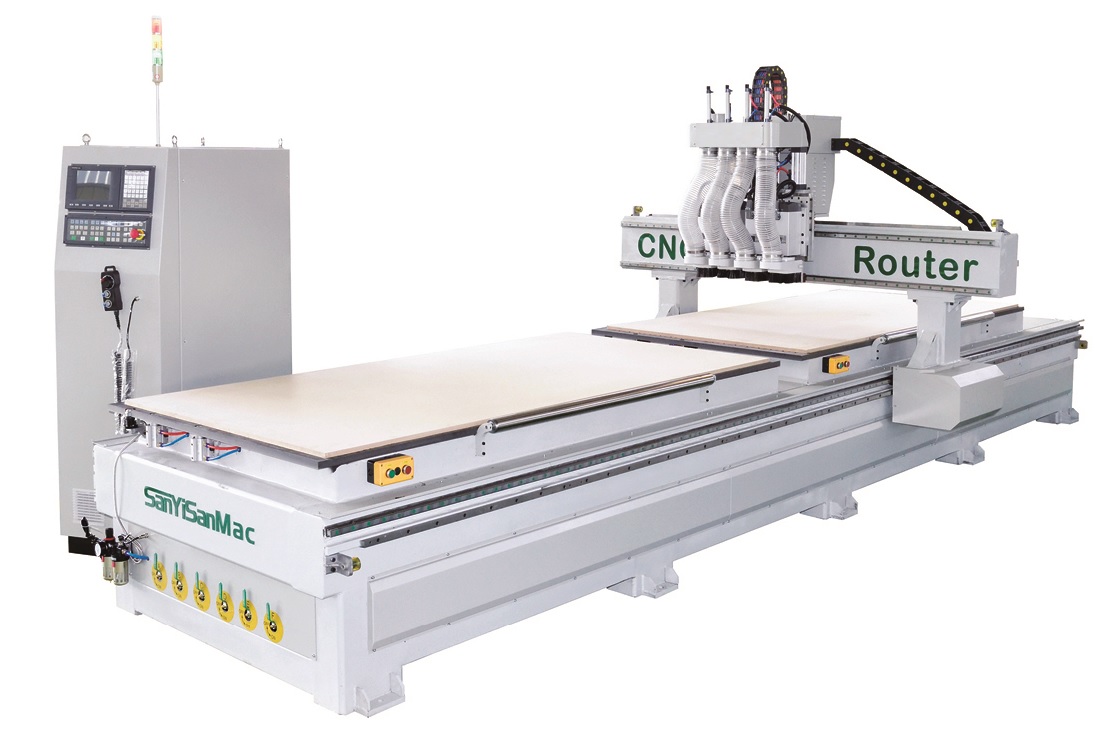

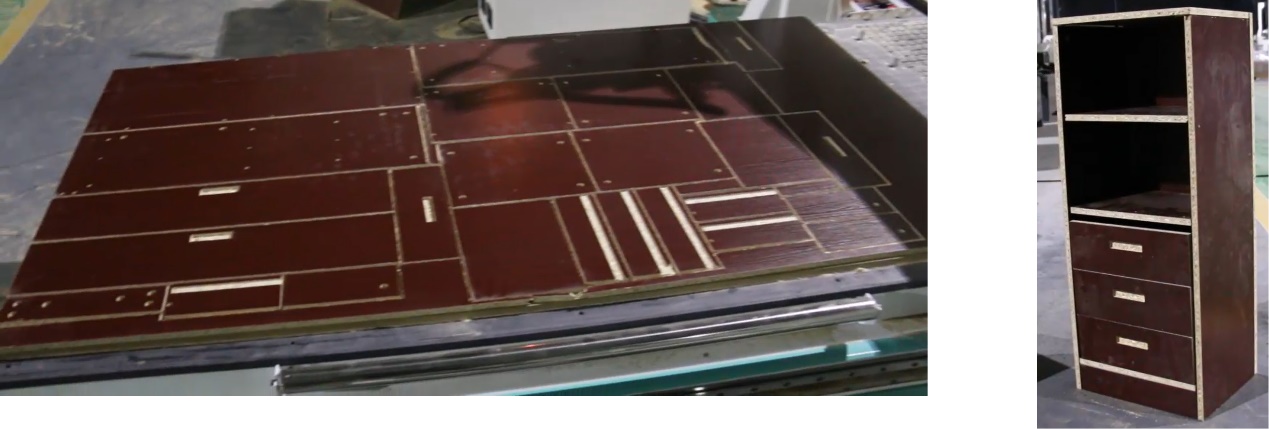

CNC Router is mainly divided into single-head CNC cutting machine, multi-process cutting machine, and automatic tool change machining center. CNC cutting machine is a special equipment for cutting, drilling and milling grooves for customized panel furniture. It is suitable for wardrobe cabinets, cabinets, computer desks, panel furniture, office furniture, wooden speakers, wooden kitchen utensils and other panel furniture. Auxiliary processing such as plane blanking, milling, chamfering, punching, and engraving. Because of its automatic processing and production, time-saving, labor-saving and cost-saving advantages, it has been trusted by the majority of furniture manufacturers.

Applicable industries: panel furniture, cabinet cabinets, wardrobe cabinets, custom furniture, office furniture and interior doors and sliding doors, cabinet door panels and other industries.

Main functions: automatic tool change, cutting, milling, hollowing, slotting, punching, etc.

The four-spindle CNC Router is an economical and affordable model with four heads automatically switched, which can realize four-step continuous work. The four-process CNC cutting machine can realize both the cabinet body and the door panel, that is, both the cabinet body and the door panel can be processed, but the production efficiency is lower than that of the double-process drilling cutting machine, which is more suitable for some small and medium-sized furniture companies that are just starting out. The disc tool-changing machining center is composed of a 9kw main shaft and a row-drilling tool magazine. This tool magazine can contain 8 tools, 12 tools, 16 tools, and 20 tools. In the process of processing, the 9kw spindle will automatically go to the tool magazine to fetch the tool according to the needs. This 9kw spindle can be completed whether it is processing door shapes, engraving patterns, hollowing out patterns, cutting and cutting grooves. It is suitable for those who want to make cabinets and door shapes, and add some hollow lattice carvings from time to time. Use the disc tool-changing machining center to make cabinet door panels, and automatically change the tool to complete all the processes of cabinet door processing at one time, eliminating the need for manual tool change, greatly improving the processing efficiency and product quality.

Post time: Jun-21-2021